AR-P 3100 series positive photoresist

Adhesion enhanced positive photoresist

…

AR-P 3100 series product brief 產品說明

AR-P 3100 系列,產品配方強化與基板介面的接著度,適合各類精密微影製程的正型阻劑。

目前產品依配方與厚度範圍有如下序號:

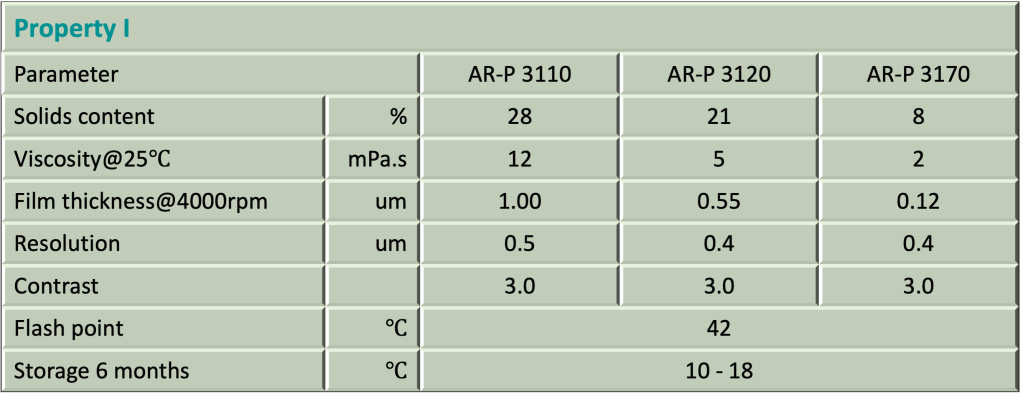

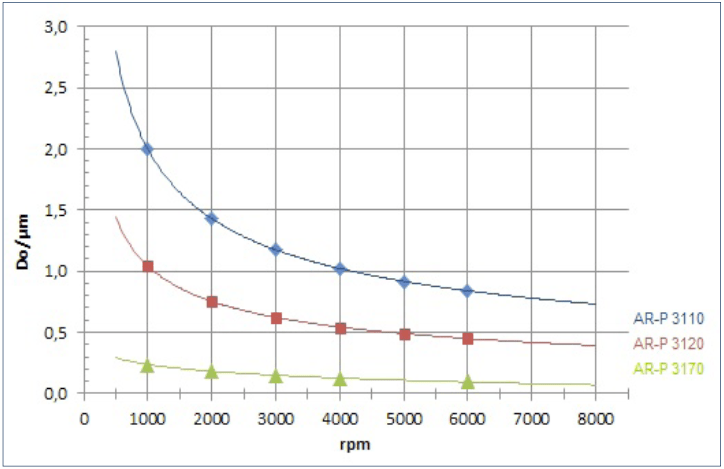

| Property |

| AR-P 3110 | AR-P 3120 | AR-P 3170 |

| Film thickness@4000rpm |

| 1 um | 0.55 um | 0.12 um |

| Resolution |

| 0.5 um | 0.4 um | 0.4 um |

| Contrast |

| 3.0 |

| Flash point |

| 46 ℃ |

| Storage 6 months*1 |

| 10 – 18 ℃1 |

| Production status*2 |

| routine1 |

- Product is guaranteed 6 months shelf life from the date of sale if stored correctly.

在正確儲存條件下,產品保證的有效期限為銷售日起6個月。

Product can also be used without guaranteed until the date indicated on the label.

在無提供保證的情況下,產品可使用至標籤上所示的有效期。 ↩︎ - Product status:

routine:產品固定排程生產,交貨期約2-4週。

on-demand:產品無固定排程生產,需先詢價。可能有最小訂購量(MOQ)或需待批次生產排程。 ↩︎

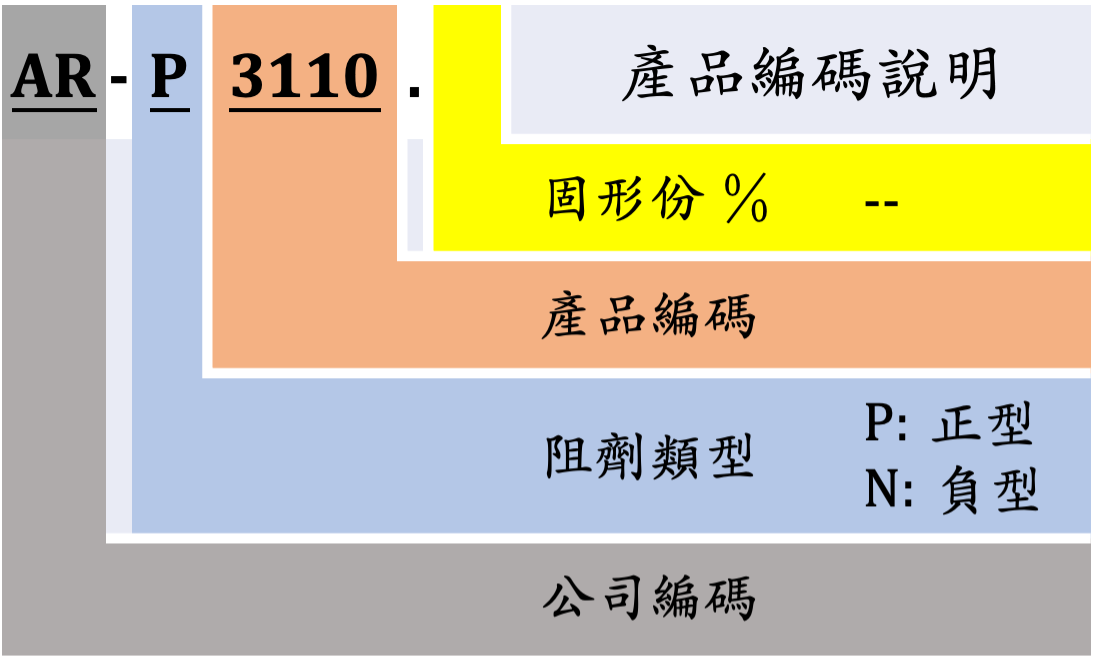

產品編碼說明

…

Packing & shipping 產品包裝與出貨

packing 產品包裝

✅ 250 ml/瓶

✅ 1 L/瓶

其它包裝可依需求研擬增加

shipping 產品出貨

✅ 2 – 4 週。德國運出。

…

Product features 產品特性

- broadband UV, i-line, g-line

曝光波長: 寬頻紫外線, i-line (365nm) , g-line (436nm) - high photosensitivity, high resolution

高敏感度,高解析度 - strong adhesion to critical glass/chromium surfaces for extreme stresses during wet-chemical etching processes

對玻璃,鉻等介面接著度良好,適合濕蝕刻製程 - for the production of CD masters and lattice structures

適合CD母片及各式點陣結構 - AR-P 3170 also suitable for laser interference lithography

AR-P 3170可用於雷射干涉微影 - plasma etching resistant

耐電漿蝕刻 - combination of novolac and naphthoquinone diazide

主要成份為酚醛樹酯及叠氮基萘醌 - safer solvent PGMEA

使用較安全溶劑丙二醇甲醚醋酸酯

…

Product properties 產品物性

…

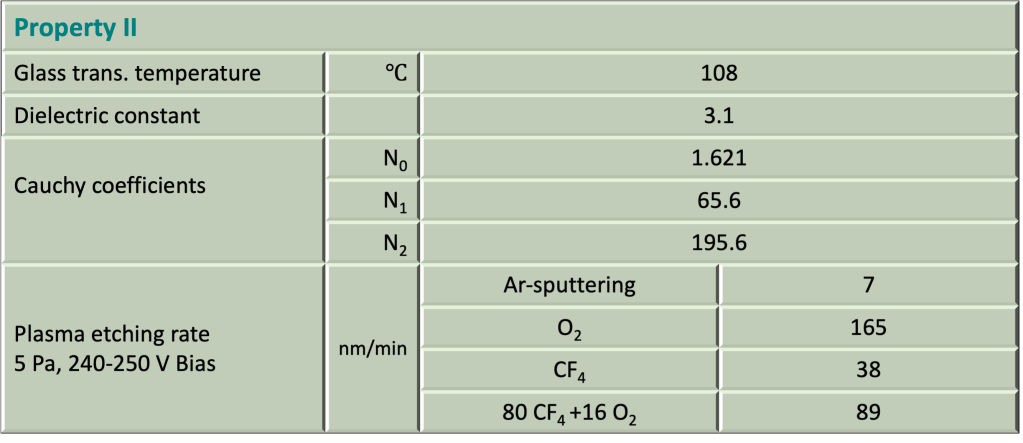

AR-P 3100 series Spin curve 塗佈曲線

…

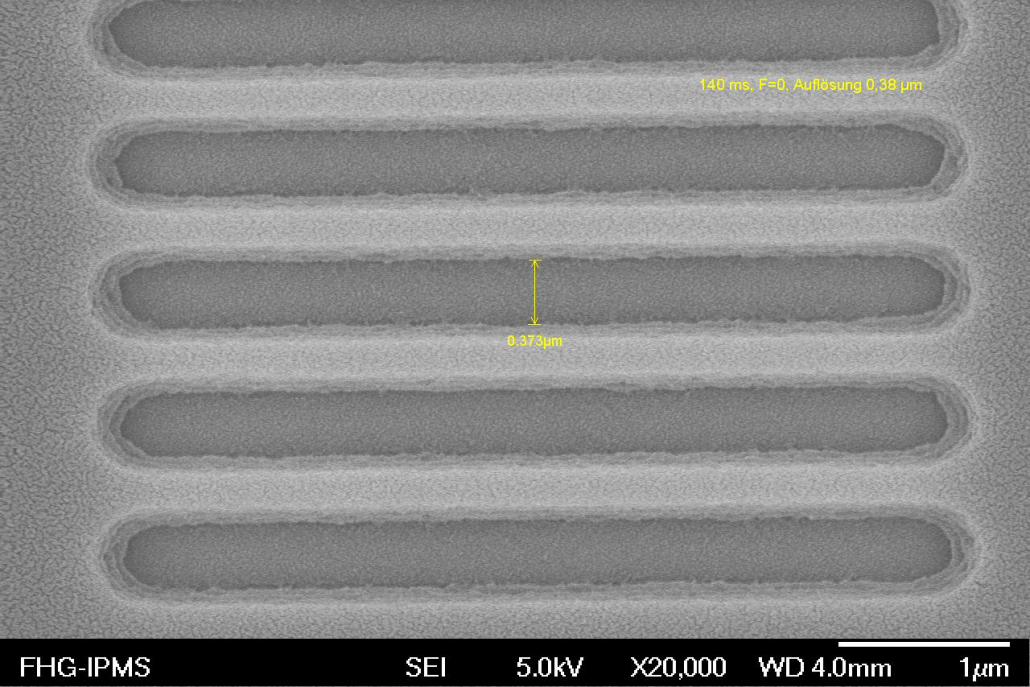

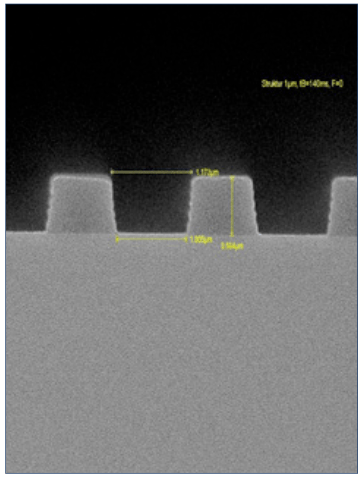

Structure and resolution 結構與解析度

Structure resolution

AR-P 3120:

Film thickness 0.6 μm Resist structures 0.38 μm L/S

Resist structure

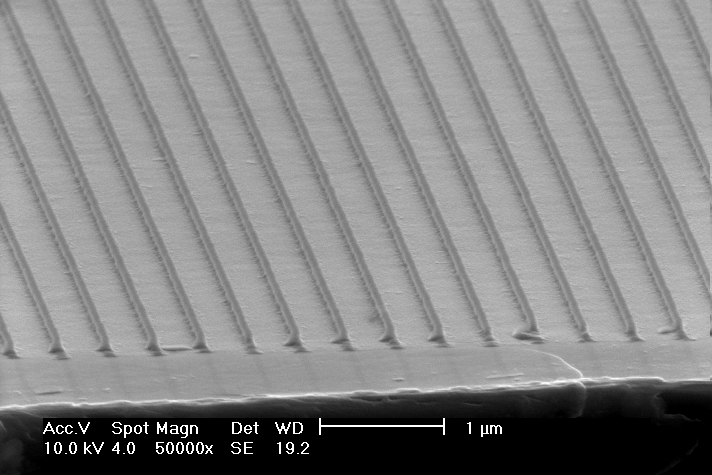

AR-P 3170:

70-nm-lines generated by laser interference lithography

…

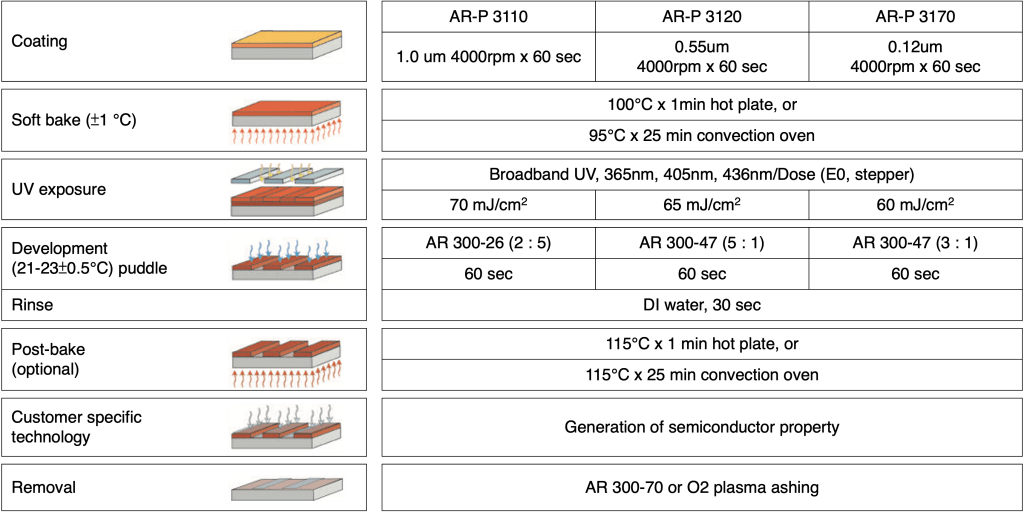

Process baseline 製程參數

This diagram shows exemplary process steps for AR-P 3100 resists. All specifications are guideline values which must be adapted to own specific conditions. For further information on processing, 👉“ Detailed instructions for optimum processing of photoresists”. For recommendations on wastewater treatment and general safety instructions, 👉”General product information on Allresist photoresists”.

表列為AR-P 3100系列產品製程參數的範例。所有參數為參考值,使用者應依設備環境實際狀況加以調整。

Development recipe

…

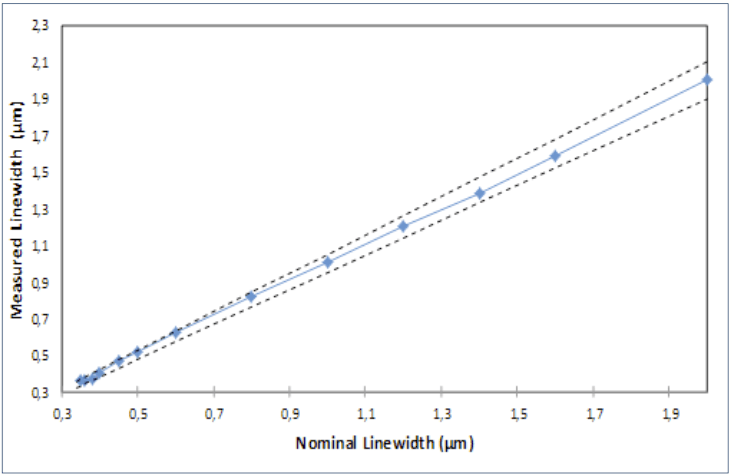

Reference data 參考資料

Linearity

Up to a structure width of 0.38, a very good agreement is obtained. REM measurement: Thickness 560 nm, i-line stepper (NA: 0.65 NA), Developer AR 300-47 1 : 1.

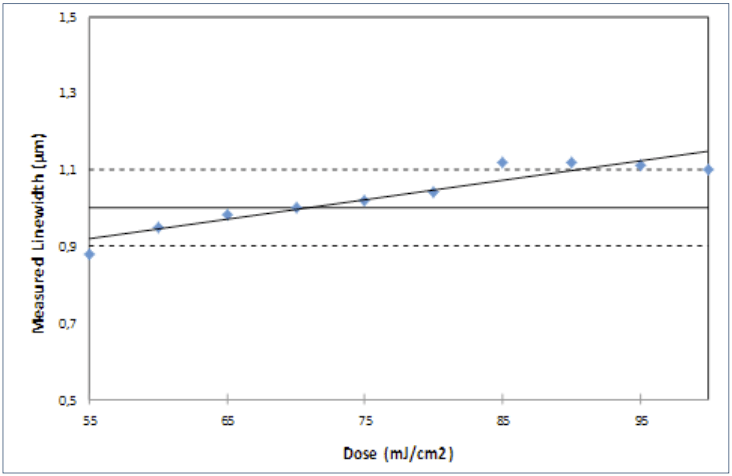

Optimum exposure dose

Underexposure leads in the case of complete development (more than 55 ml/cm2) to narrower trenches, while overexposure results in a widening of trenches.

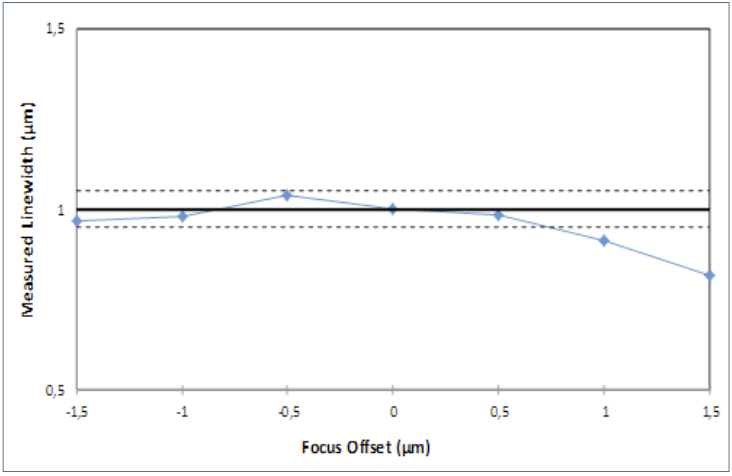

Focus variation

The intended structure sizes can here be realized by varying the focus between -1.5 to 0.8 (parameter see graphic linearity).

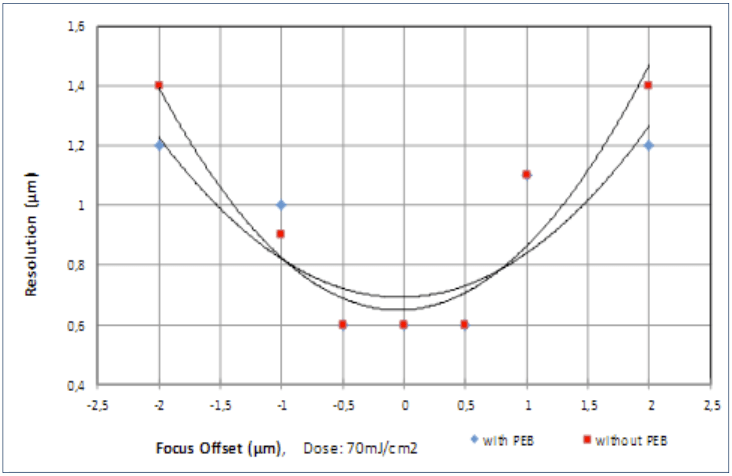

Focus variation (with and without PEB)

Without PEB, a higher resolution is obtained since the focus curve is steeper (PEB, 90 °C, 60 s).

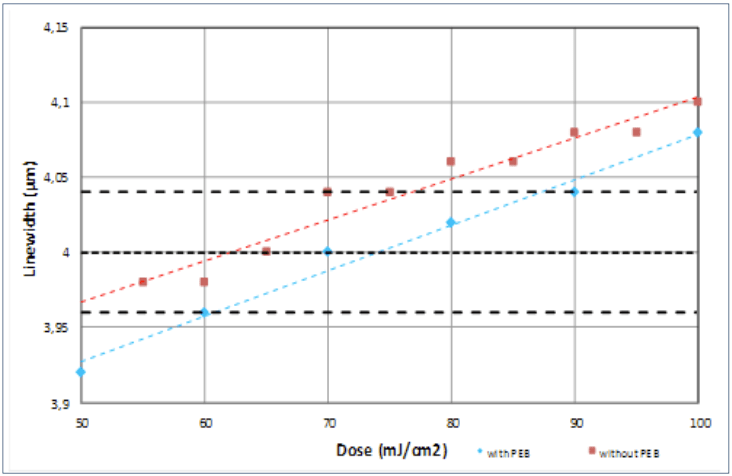

Optimum exposure dose

Optimum dose, with hard bake (110 °C) and without hard bake. The additional hard bake requires 15 % more light (PEB, 90 °C, 60 s).

Thermal properties of resist structures

Untempered

Hard bake 115℃

…