SX AR-N 8200 series (Medusa 82) e-beam lithography resist

HSQ-like, with higher process stability, shelf life and resier to remove

…

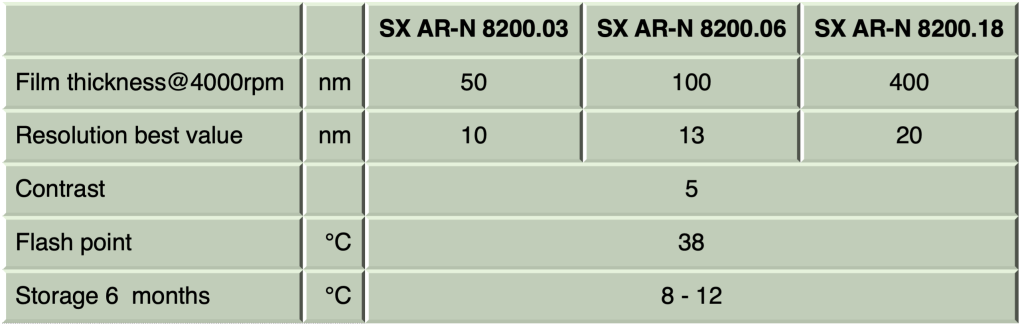

Product brief 產品簡介

AR-N 8200系列, 實驗代號Medusa 82, 為矽倍半氧烷類(silsesquioxane)負型電子束微影阻劑 (negative tone EBL resist). 與傳統HSQ resist相較, Medusa 82具有較佳製程穩定度, 較容易去除及較長的使用壽命等優點. 產品系列目前有:

SX AR-N 8200.03

SX AR-N 8200.06

SX AR-N 8200.18

…

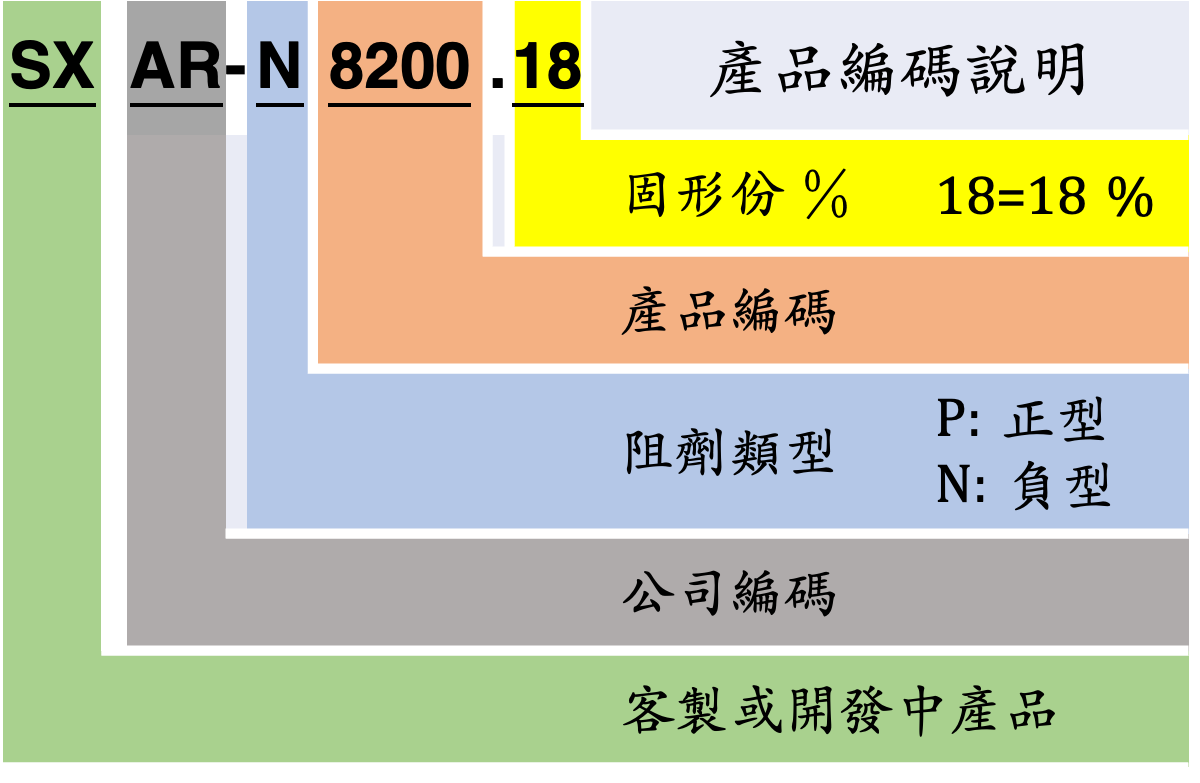

Product series & Code 產品比較及編碼說明:

…

Packing 產品包裝:

✅ 100 ml /瓶

✅ 250 ml /瓶

✅ 1 L /瓶

其它包裝可依客戶需求增加.

Shipping 出貨:

✅ 2 – 4 週: 徳國運出

❎ 1 週: 國內庫存

(目前暫無國內庫存)

…

Product Features 產品特性

- high-resolution e-beam resist (10 nm)

高解析度電子束微影阻劑,解析度可達10nm - etch-stable resist structures available in three film thicknesses

抗蝕刻能力穩定, 三種厚度範圍產品 - comparable to HSQ, but higher process stability easier to remove, considerably higher shelf life

類似於HSQ,但製程較為穩定,也較容易去除且俱有較長的有效期限

- sensitivity is increased by a factor of 20 if an additional tempering step is applied

增加曝後烤步驟可提高敏感度達20倍 - silsesquioxane dissolved in 1-methoxy-2-propanol

主要成份為矽倍半氧烷類溶於丙二醇甲醚(PGME)

…

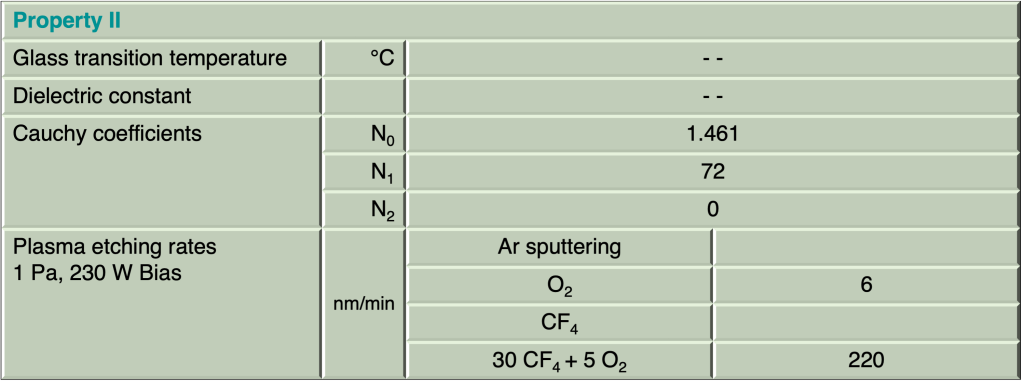

Product Properties 產品物性

…

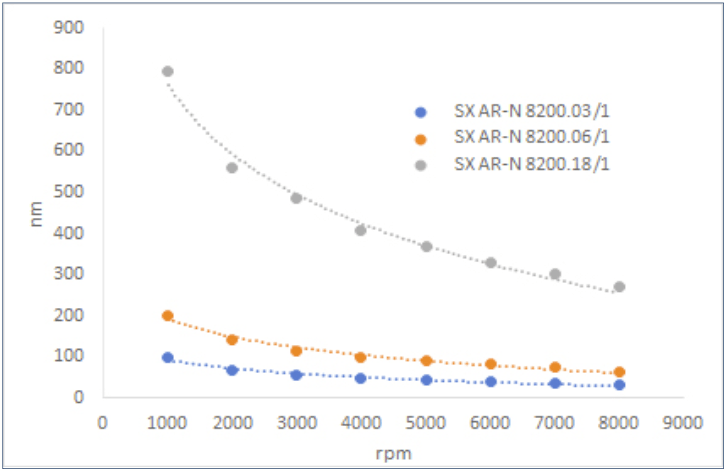

Spin curve 塗佈曲線

● SX AR-N 8200.03

● SX AR-N 8200.03

● SX AR-N 8200.03

…

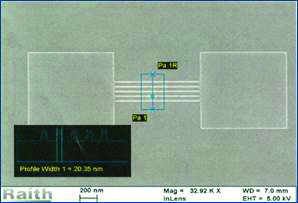

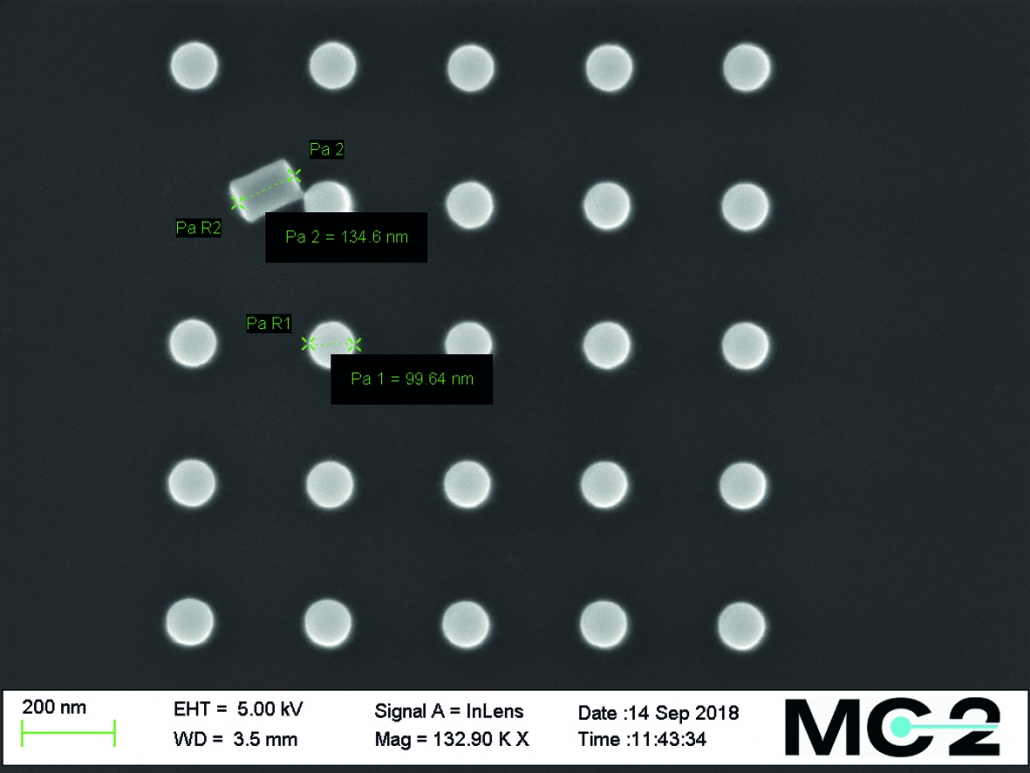

Structure resolution

11 nm structures produced with SX AR-N 8200.03/1

Resist structures

100 nm bars with SX AR-N 8200.06/1

Process parameters

| Substrate | 4″ Si wafer |

| Soft bake | 150℃x10min, hot plate |

| Exposure | Raith Pioneer 30 KV |

| Development | AR 300-44, 90sec 23℃ |

…

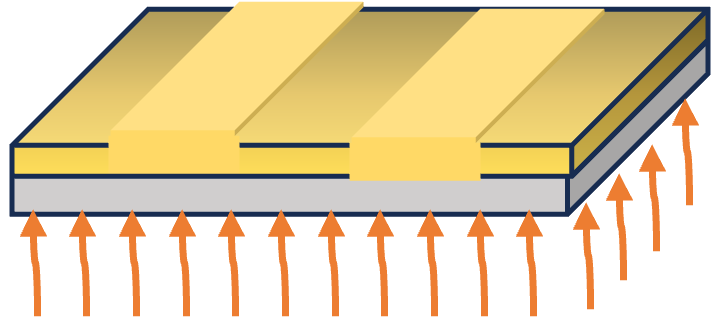

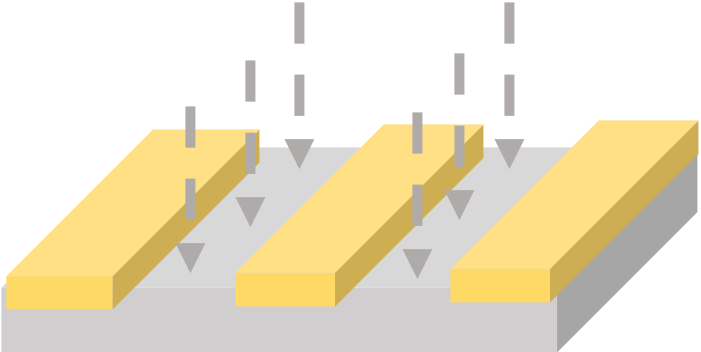

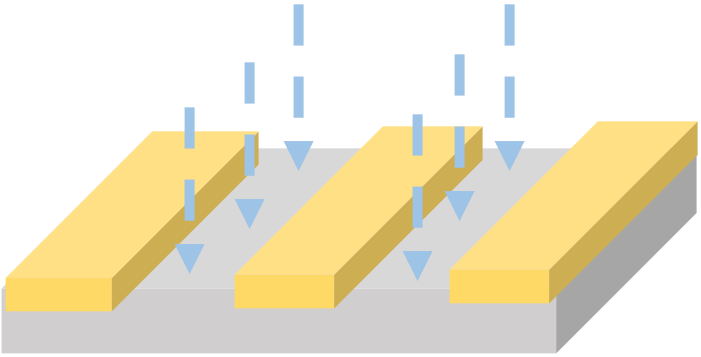

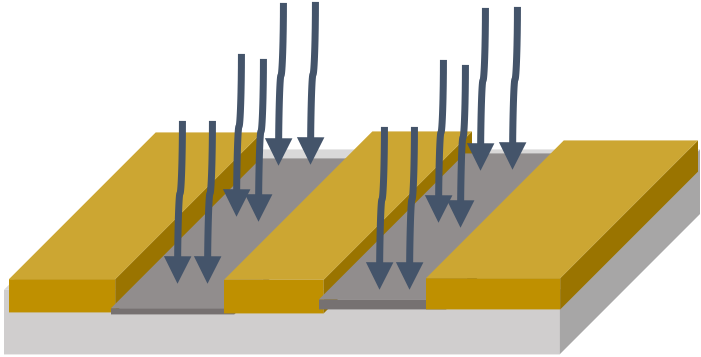

Process baseline 製程參數

This diagram shows exemplary process steps for SX AR-N 8200 series resists. All specifications are guideline values which have to be adapted to own specific conditions. For further information on processing, 👉“Detailed instructions for optimum processing of e-beam resists”. For recommendations on waste water treatment and general safety instructions,

👉”General product information on Allresist e-beam resists”.

表列為SX AR-N 8200系列產品製程參數的範例. 所有參數為參考值,使用者應依設備環境實際狀況加以調整

| Process | SX AR-N 8200.03 | SX AR-N 8200.06 | SX AR-N 8200.18 |

|---|---|---|---|

Coating | 50 nm @4000 rpm | 100 nm @4000 rpm | 400 nm @4000 rpm |

soft-bake (±1℃) | 150 ℃ x 10 min/hot plate | ||

| e-Beam exposure dose (E0)  | Raith Pioneer, acceleration voltage 30 kV E0: dose | ||

| 1300 uC/cm2 | 1300 uC/cm2 | 2000 uC/cm2 | |

Post exposure bake | To enhance the sensitivity 170 °C, 10 min,hot plate | ||

| 60 uC/cm2 | 60 uC/cm2 | 85 uC/cm2 | |

| Development 21-23℃ puddle  | AR 300-44 90 sec | ||

Rinse | DI water, 30 sec | ||

| Customer specific process  | |||

Removal | 2 n NaOH | ||

…

Note on stability 穩定性說明

Liquid Medusa resists are stable for up to 6 months if kept refrigerated at least 8 – 12 °C. Coated substrates can be stored under normal conditions and processed without any loss of sensitivity or resolution even after several weeks. Current studies show that irradiated substrates can be processed even after 21 days without significant loss of sensitivity.

Medusa 82阻劑保存在8-12℃環境下,有效期限為6個月. 阻劑已塗佈在基板上,在正常情況下仍可維持其敏感度或解析度至數週. 目前研究顯示,已曝光的基板在21天後顯影,其敏感度幾乎不變.

…

Process instruction 製程參數

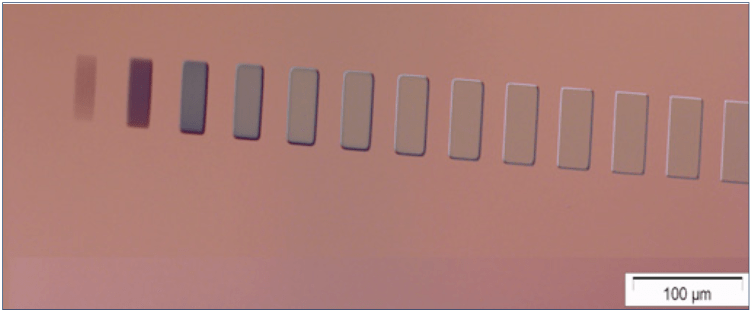

The sensitivity changes in dependence on the acceleration voltage. While 1300 μC/cm2 is sufficient at 30 kV, this value increases to 4000 μC/cm2 at 100 kV. Figure 1 shows the corresponding dose scale (90 s AR 300-44, 23 °C). Recommended are development times of 60-90 s.

Medusa 82的敏感度會隨著使用的加速電壓改變. 加速電壓在30kV時只需約1,300 uC/cm2的劑量; 在100kV時則需增加到4,000 uC/cm2. 左下圖1為不同曝光劑量下顯影的結果(顯影劑AR 300-44, 23℃, 顯影時間 60-90 sec)

Figure 1: Dose scale (400 – 5000 µC/cm²) Medusa 82. Resist: SX AR-N 8200.06/1

100 nm; coating: 60 s 4000 rpm;

soft-bake: 15 min @ 120 °C;

exposure: Raith Pioneer, 30 kV;

development: 90 s AR 300-44; 23 °C; stopping: 30 s DI water

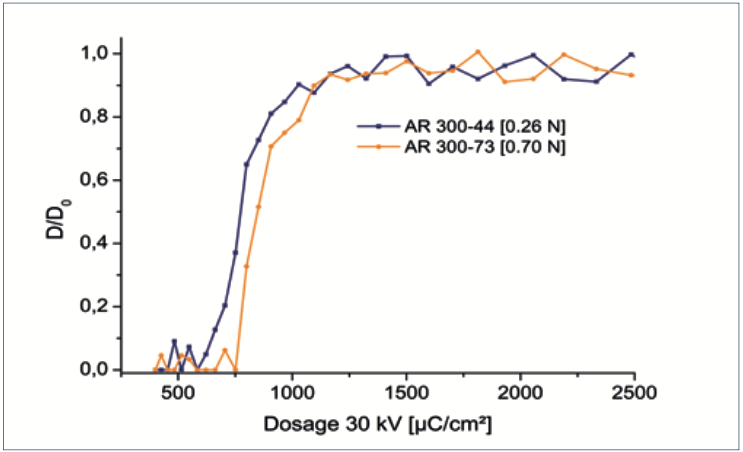

Also AR 300-46, AR 300-47 and AR 300-73 can be used for development, but the different developer concentrations affect the required development time and the dose. AR 300-44 results in a contrast of 4.7 at a required dose of 690 μC/cm², while AR 300-73 results in a contrast of 4.6 at a required dose of 785 μC/cm² under otherwise equal conditions

顯影劑AR 300-46, AR 300-47及AR 300-73皆適用,但濃度不同,所需顯影時間及曝光劑量也隨著改變. 下圖2顯示,以AR 300-44顯影,在曝光劑量690uC/cm2時,對比度達4.7. 在其它參數一樣下,以AR 300-73顯影,要達4.6對比度則需785 uC/cm2的曝光劑量

Figure 2: Influence of developer concentration on contrast and dose

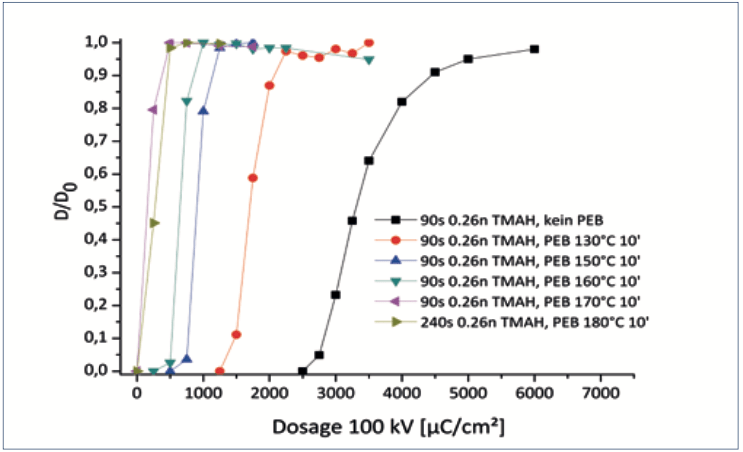

To increase sensitivity, a post exposure bake may be required after irradiation, which increases the sensitivity the increases by a factor of 8 at 100 kV and even by a factor of 20 at 30 kV. In addition, also the contrast is increased.

增加曝後烤步驟可增加Medusa 82的敏感度. 在100kV加速電壓,曝光後加以曝後烤可使敏感度增約8倍; 在30kV則增加約20倍. 下圖3為不同曝後烤條件下敏感度的變化.

Figure 3: Influence of post exposure bake temperature on the dose.

Resist: SX AR-N 8200.06/1;

coating: 60 s 4000 rpm;

soft- bake: 10 min;

exposure: 100 kV;

post exposure bake 10 min;

development: 90 s AR 300-44; 23°C;

stopping: 30 s DI water

…