SX AR-PC 5000/41 protective coating

HF and KOH resistant coating for backside protection

…

SX AR-PC 5000/41 product brief 產品簡介

SXAR-PC 5000/41產品為保護型塗佈,耐氫氟酸/氫氧化鉀,適合晶背保護.

搭配光阻以雙層製程可進行圖案(pattern)設計

…

SX AR-PC 5000/41 packing and shipping 產品包裝與出貨

Packing 產品包裝:

✅ 250 ml/瓶

✅ 1 L/瓶

其它包裝可依客戶需求增加.

Shipping 出貨:

✅ 2 – 4 週: 徳國運出

❎ 1 週: 國內庫存

(目前暫無國內庫存)

…

SX AR-PC 5000/41 features 產品特性

- not light-sensitive > 300 nm, no yellow light required

對波長> 300nm無反應,無需於黃光區作業 - protection of wafer backside when etching the front side up to 80℃; e.g., with 40% caustic potash, 50% hydrofluoric acid, BOE

晶圓蝕刻時做為晶背保護塗佈,例如:40% 氫氧化鉀,50%氫氟酸,氫氟酸緩衝液等80℃的蝕刻製程 - in two-layer system structurable with AR-P 3250 or AR-N 4400-05/10; plasma etching resistant.

與正負型光阻(AR-P 3250或AR-N 4400-05/10)雙層製程可製作保護塗層塗案. 保護層

耐電漿蝕刻 - high-melting modified hydrocarbons

成份含高熔點改良的碳氫化合物 - solvent ethylbenzene

使用乙苯溶劑

…

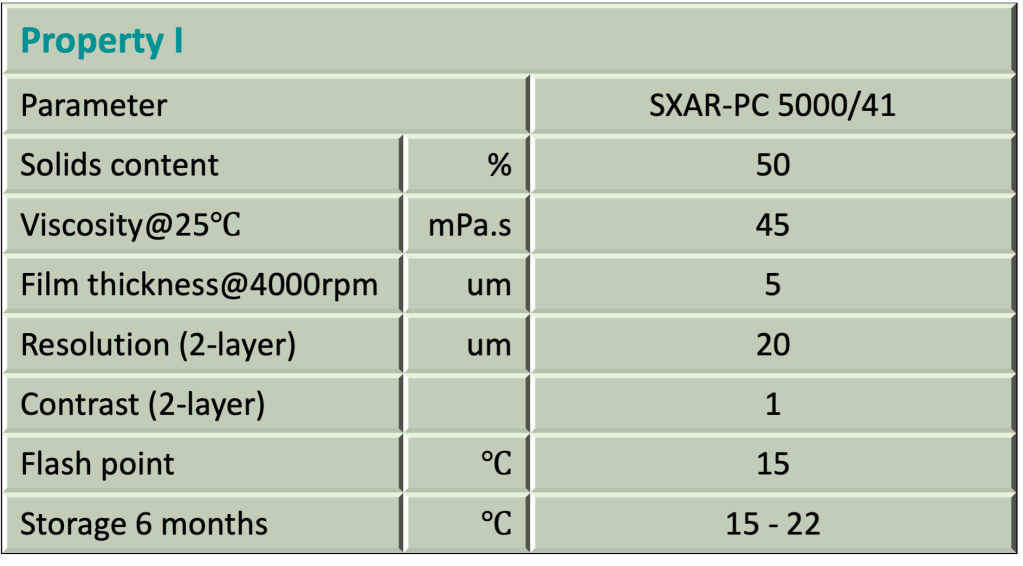

SX AR-PC 5000/41 properties 產品物性

…

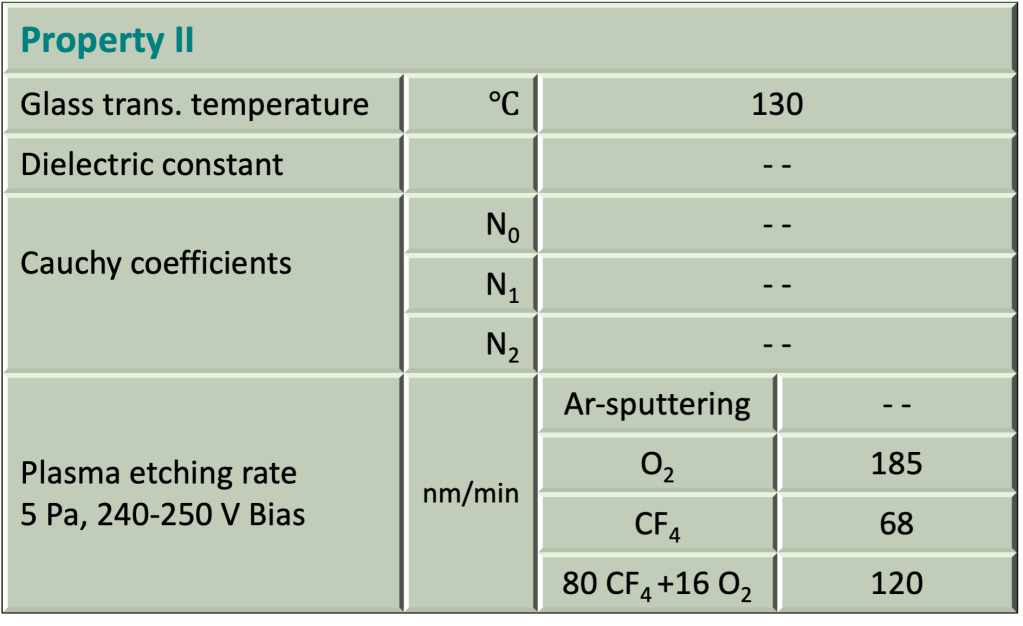

SX AR-PC 5000/41 Spin curve 塗佈曲線

…

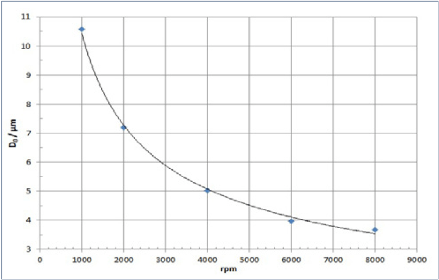

Application example

Resist structures

Two-layer structuring with SX AR-PC 5000/41 and AR-P 3250 (on the left resist mask, on the right after etching in glass)

Topology of the backside

5 μm thick layer with glass wafer provided by the IDM

Process chemicals

| Adhesion promoter | AR 300-80 new |

| developer | X AR 300-74/1 |

| Thinner | X AR 300-74/1 |

| Remover | X AR 300-74/1 |

…

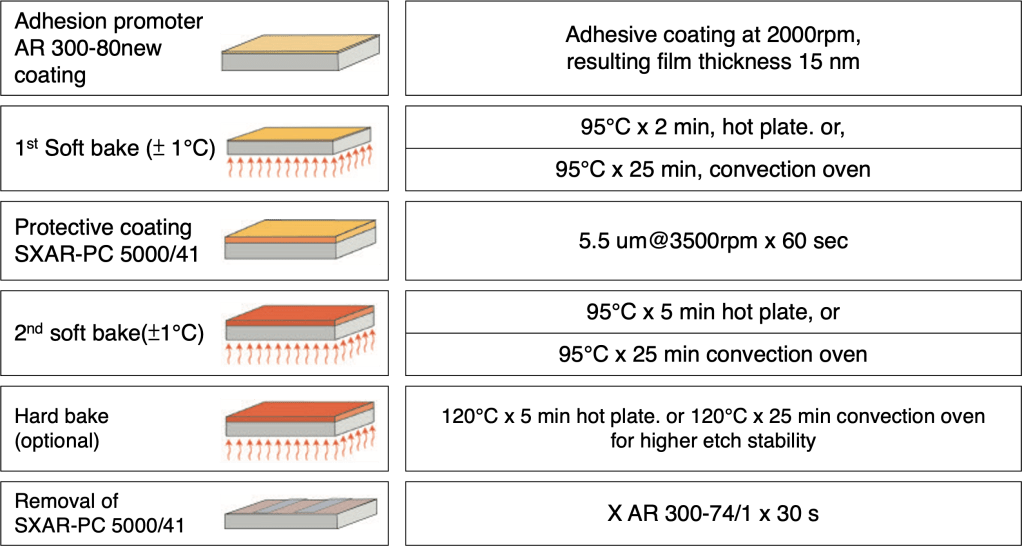

Process baseline one-layer process 單層製程參數

This diagram shows exemplary process steps for the protective coating SXAR-PC 5000/41. All specifications are guideline values which must be adapted to own specific conditions.

圖示SXAR-PC 5000/41系列產品製程參數的範例. 所有參數為參考值,使用者應依設備環境實際狀況加以調整

Processing instructions 單層參數說明

Coating: A spin speed of 1000 rpm is recommended, since wafer edges are optimally protected due to the slight wrapping effect at a film thickness of approx. 10 μm during spin deposition.

塗佈:建議轉速約1000轉,可得厚度約10um且晶片邊緣有包覆效果

Etch process: The protective layer is not attacked over hours.

蝕刻::保護塗層可耐蝕刻幾個小時.

Note: The protective film is not dissolved in acetone or isopropanol. For removal or cleaning of equipment, the respective thinner must be used.

附註::保護塗層不溶於丙酮或異丙醇. 去除或相關設備清洗需使用指定的稀釋劑

…

Process baseline two-layer process 雙層製程參數

This diagram shows exemplary process steps for the protective coating SXAR-PC 5000/41. All specifications are guideline values which must be adapted to own specific conditions.

圖示SXAR-PC 5000/41系列產品製程參數的範例. 所有參數為參考值,使用者應依設備環境實際狀況加以調整

Processing instructions 雙層參數說明

Coating:

A spin speed of 1000 rpm is recommended, since wafer edges are optimally protected due to the slight wrapping effect at a film thickness of approx. 10 μm during spin deposition.

塗佈:建議轉速約1000轉,可得厚度約10um且晶片邊緣有包覆效果

Etch process: The protective layer is not attacked over hours up to 80℃.

蝕刻::保護塗層可耐80℃蝕刻溫度幾個小時.

Note: The protective film is not dissolved in acetone or isopropanol. For removal or cleaning of equipment, the respective thinner must be used.

附註::保護塗層不溶於丙酮或異丙醇. 去除或相關設備清洗需使用指定的稀釋劑

…