AR-PC 504 protective coating

adhesion-enhanced KOH-resistant resists

Wafer backside protection coating for the application of deep trench

…

AR-PC 504 product brief 產品簡介

AR-PC 500 series 系列產品為保護型塗佈,耐氫氧化鉀,適合濕蝕刻製程晶背保護. 系列產品目前有:

AR-PC 503 :PMMA高分子,溶劑為氯苯(chlorobenzene)。成份中參雜深色染料以保護敏感元件。

AR-PC 504 :PMMA高分子,溶劑為氯苯(chlorobenzene)。

AR-PC 5040:PMMA高分子,溶劑採用較安全的甲氧苯(anisole)。

…

AR-PC 504 properties and features 產品物性與特性

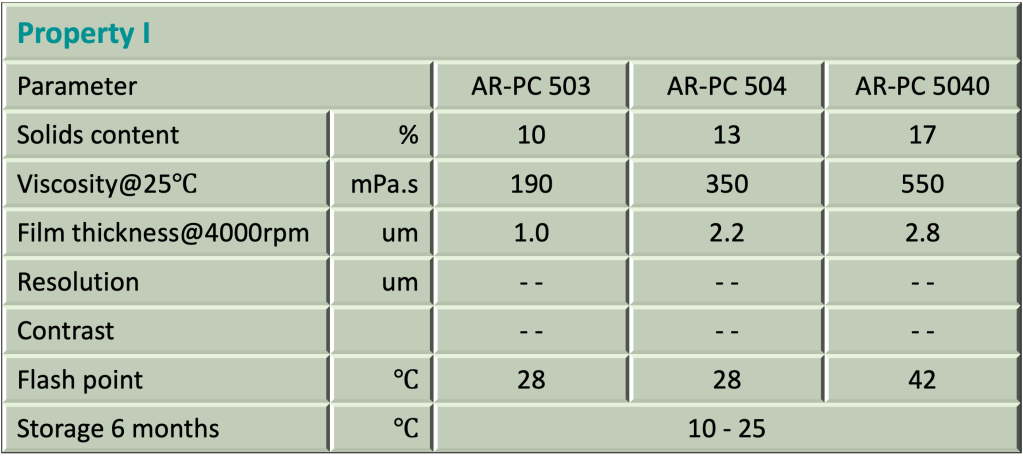

Properties

| Film thickness | 2.2 um@4000rpm |

| Flash point | 28 ℃ |

| Storage 6 months | 18 – 25 ℃ |

* Product is guaranteed 6 months shelf life

from the data of sale if stored correctly.

在正確的儲存條件下,產品保證的有效期為銷售日起6個月

* Product can also be used without

guarantee until the date indicated on the label.

在無提供保證的情況下,產品可使用至標籤上所示的有效期.

Features

- not light-sensitive > 300 nm, no yellow light required

對波長> 300nm無反應,無需於黃光區作業 - protection of wafer backside when etching the front side

晶圓蝕刻時做為晶背保護塗佈 - offer reliable protection against mechanical damage during handling and transport

也可在作業或運輸時提供晶圓保護以避免破壞 - temperature-stable up to 250°C

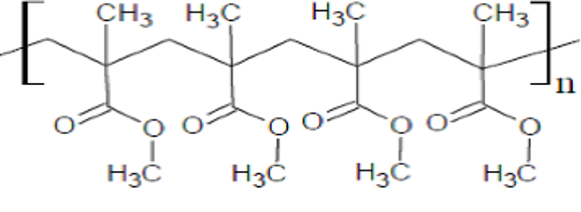

高溫達250℃仍可保持穩定 - PMMA with different molecular weights, AR-PC 503 in addition dyed dark

成份含不同分子量的聚甲基丙烯酸甲酯(PMMA),AR-PC 503另添加黑色染料 - solvent chlorobenzene

使用氯苯為溶劑

…

AR-PC 504 packing and shipping 產品包裝與出貨

Packing 產品包裝:

✅ 250 ml/瓶

✅ 1 L/瓶

其它包裝可依客戶需求增加.

Shipping 出貨:

✅ 2 – 4 週: 徳國運出

❎ 1 週: 國內庫存

(目前暫無國內庫存)

…

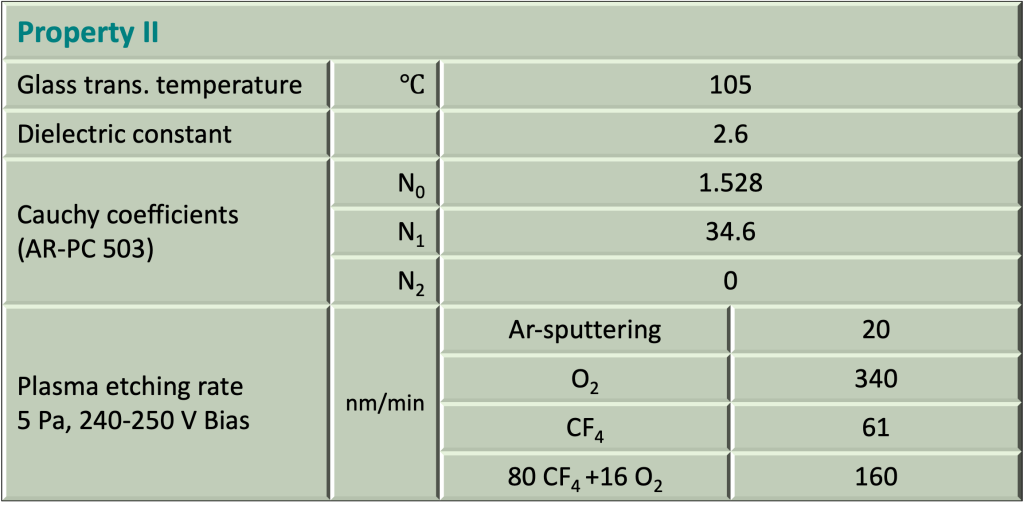

AR-PC 500 series product comparison 系列產品物性比較

…

AR-PC 500 series Spin curve 塗佈曲線

● AR-PC 5040

● AR-PC 504

● AR-PC 503

…

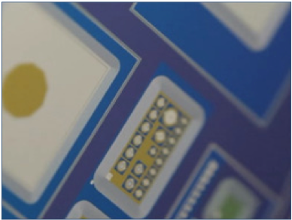

Application example

Photo of coated wafer

Protective coating AR-P 503 covering sensitive structures

Topology of the backside

Protective coating AR-PC 504 covering sensitive structures

…

Process baseline 製程參數

This diagram shows exemplary process steps for AR-PC 500 series resists. All specifications are guideline values which must be adapted to own specific conditions. For further information on processing, 👉 “ Detailed instructions for optimum processing of photoresists”. For recommendations on wastewater treatment and general safety instructions, 👉 ”General product information on Allresist photoresists”.

圖示AR-PC 500系列產品製程參數的範例. 所有參數為參考值,使用者應依設備環境實際狀況加以調整

…

Process instruction 製程參數說明

Pre-treatment prior to coating:

The protective effect during etching can be extended to up to 8 hours if the surface is pretreated with adhesion promoter AR 300-80. The coating is preferably performed at 4000 rpm. After tempering at 180 °C for 2 min (hot plate), a uniform, 15 nm thin layer of adhesion promoter is formed (-> Product information AR 300-80)

塗佈前處理(增黏處理):

以AR 300-80增黏處理可使保護塗層於蝕刻時保護性增至8小時. 增黏塗層建議以4000轉塗佈再以180℃在熱盤軟烤2分鐘,可獲得15nm均勻的增黏塗層。 (細節請參考AR 300-80產品資訊)

Coating:

A rotational speed of 1000 rpm is recommended for protective coatings, since at a film thickness of 2 – 5 μm wafer edges are best protected due to a certain “edge wrapping” of the resist. At higher spin speeds or if 6-inch wafers and above are used, the relatively high amount of resist which is deposited on the wafer may cause the so-called candy-floss effect. Low spin speeds, local exhaustion or removal of the “candy floss” with a glass rod during coating reduces these highly disturbing effects

保護塗層塗佈:

建議的轉速為1000轉.此轉數下,膜厚約2 – 5um,晶元邊緣亦可形成包覆。

在較高轉速的塗佈,或晶元大於6寸時,保護膠需滴定較大數量,此時容易形成”糖絲效應”。

降低轉速,排氣,或以玻璃棒移除絲狀物以減少其影響。

Tempering:

To obtain a particularly high protective effect for the fabrication of hard-baked films, tempering temperatures of 190 °C are recommended.

軟烤: 建議以 190℃ 高溫軟烤以獲得有效的保護塗層。

Etch process:

The protective coating is even after hours not attacked by 40 % KOH. Possibly occurring problems only derive from insufficient adhesive strength and can be significantly reduced with a pre-treatment with AR 300-80.

蝕刻製程:

保護塗層可耐40%氫氧化鉀幾小時的攻擊. 通常是由介面黏著度不夠而導致問題. 使用AR 300-80增黏劑可有效解決此問題.

…