AR-P 3500 (T) series standard positive photoresist

For semiconductor devices with wide process margin

…

AR-P 3500 series product brief 產品說明

AR-P 3500 系列產品為標準正型光阻,敏感度高,製程穩定,適合各類半導體製程。

目前產品依配方與厚度範圍有如下序號:

…

Packing & shipping 產品包裝與出貨

packing 產品包裝

✅ 250 ml/瓶

✅ 1 L/瓶

其它包裝可依需求研擬增加

shipping 產品出貨

✅ 2 – 4 週。德國運出。

❎ 1 週。國內庫存。

(目前暫無國內庫存)

…

Product features 產品特性

- broadband UV, i-line, g-line

曝光波長: 寬頻紫外線, i-line (365nm) , g-line (436nm) - high photosensitivity, high resolution

高敏感度,高解析度 - very good adhesion properties

與基板介面接著度良好 - 3500 T: robust processing, suitable for TMAH developer 0.26 n

AR-P 3510T/3540T製程穩定,適合四甲基氫氧化銨(TMAH 0.26n)顯影 - plasma etching resistant, temperature-stable up to 120 °C

耐電漿蝕刻,耐溫可達120℃ - combination of novolac and naphthoquinone diazide

主要成份為酚醛樹酯及叠氮基萘醌 - safer solvent PGMEA

使用較安全溶劑丙二醇甲醚醋酸酯

…

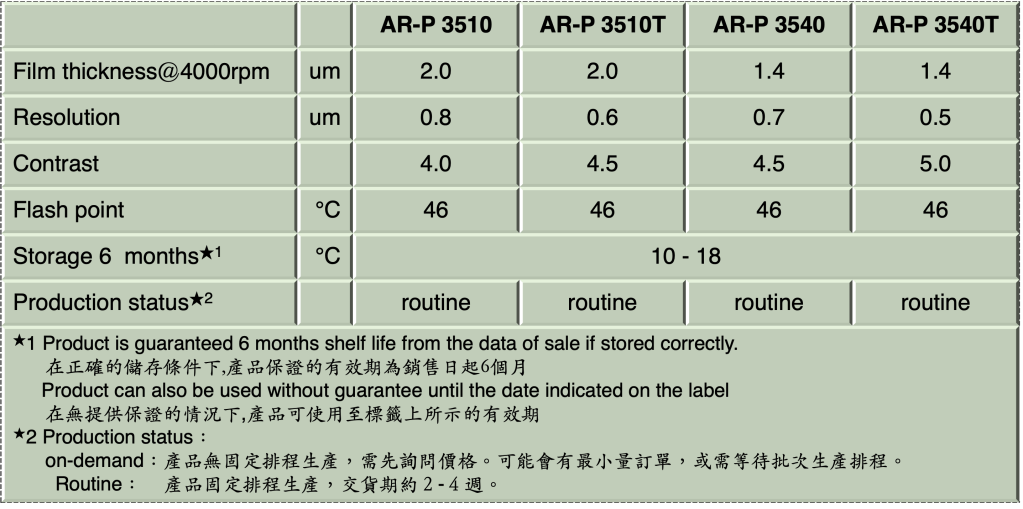

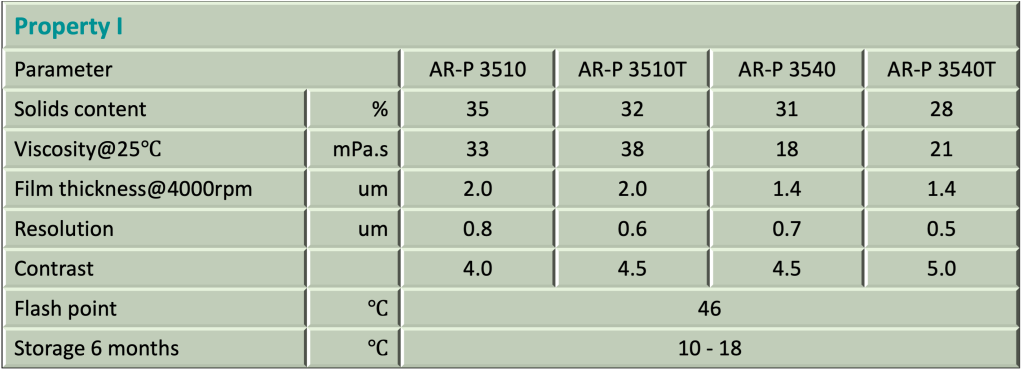

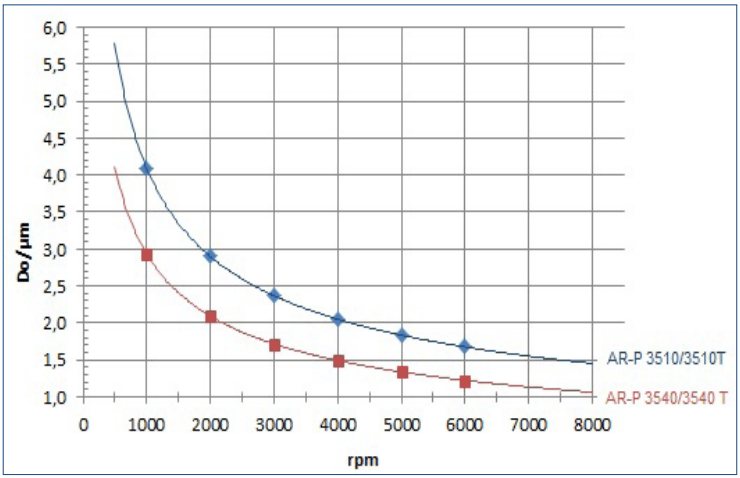

Product properties 產品物性

…

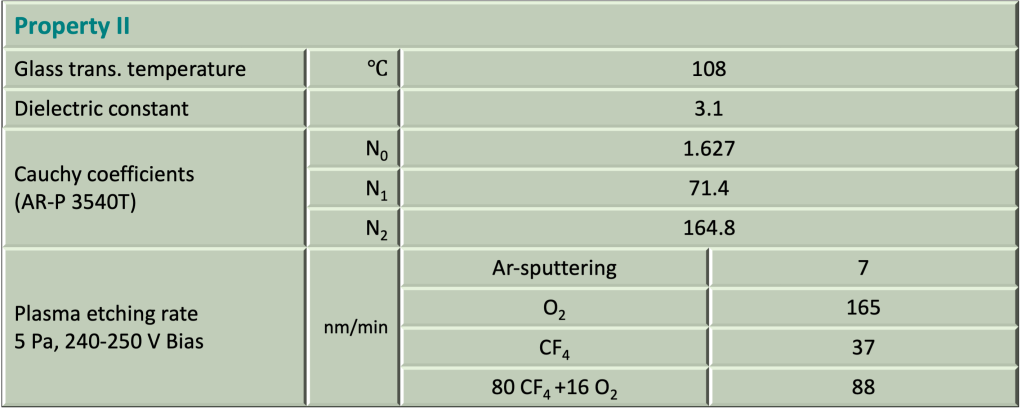

AR-P 3500 series Spin curve 塗佈曲線

…

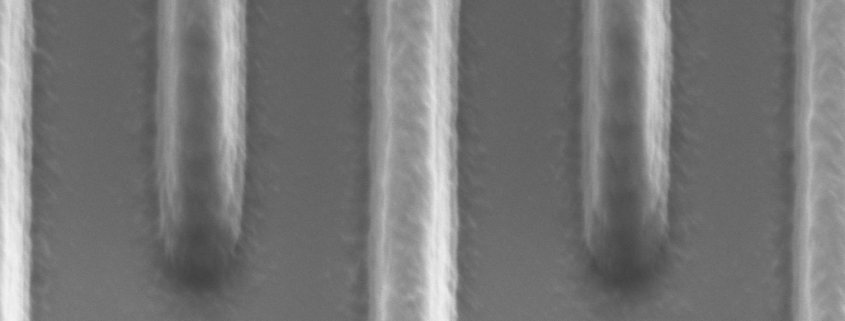

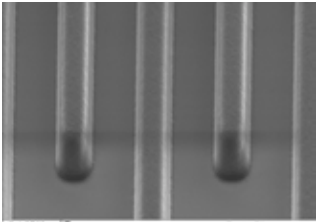

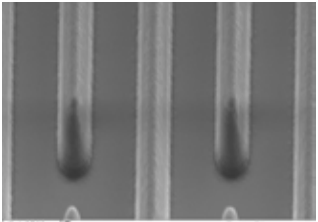

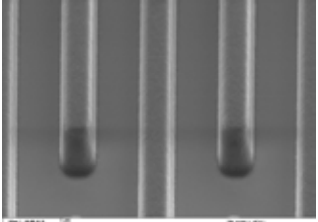

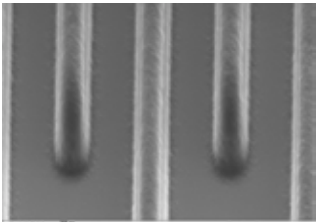

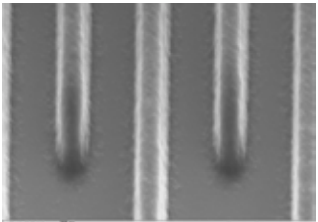

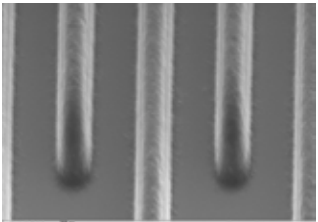

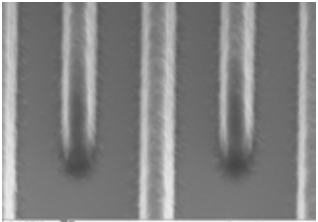

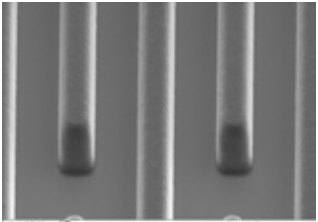

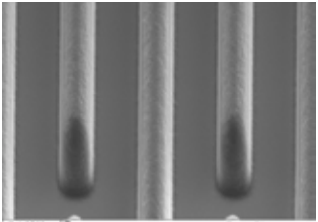

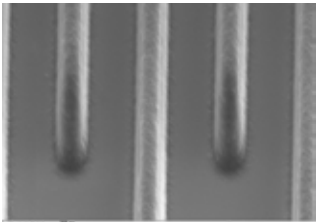

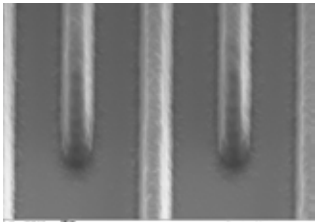

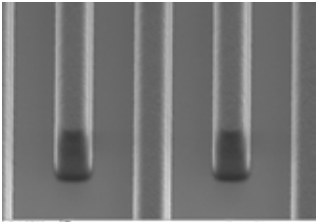

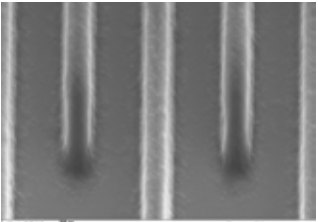

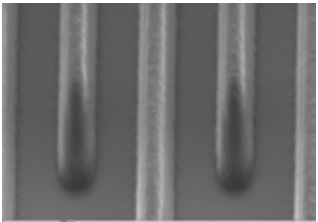

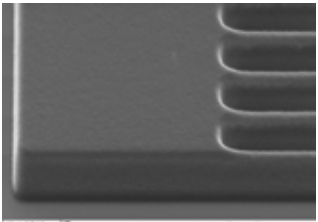

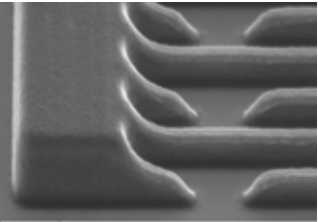

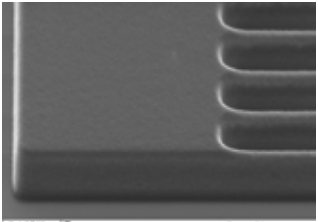

Structure and resolution 結構與解析度

Structure resolution

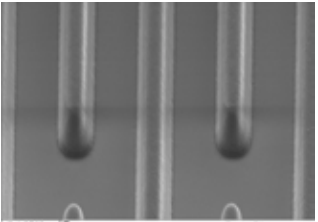

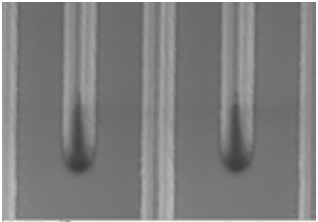

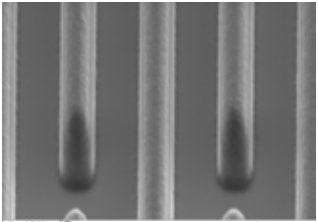

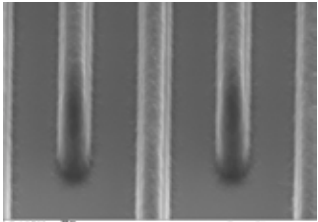

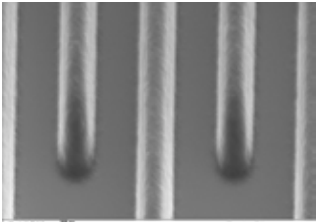

AR-P 3540 T

Film thickness 1.5 μm Resist structures 0.5 μm

Resist structure

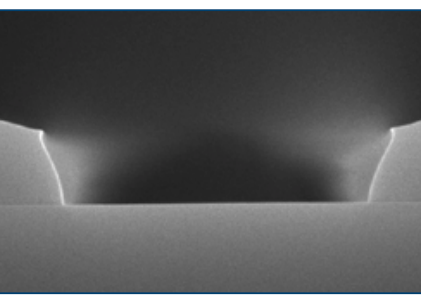

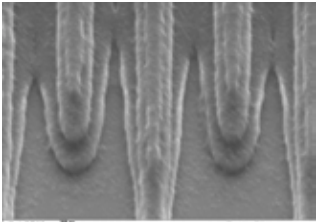

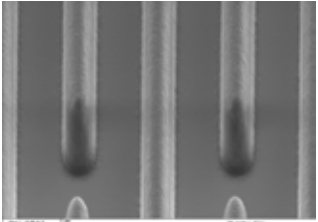

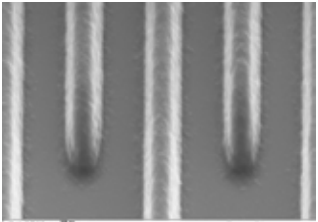

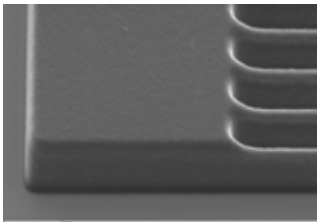

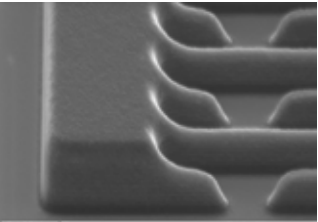

AR-P 3540Structures without hard bake

and with tempering at 140 °C (hot plate, 1 min)

…

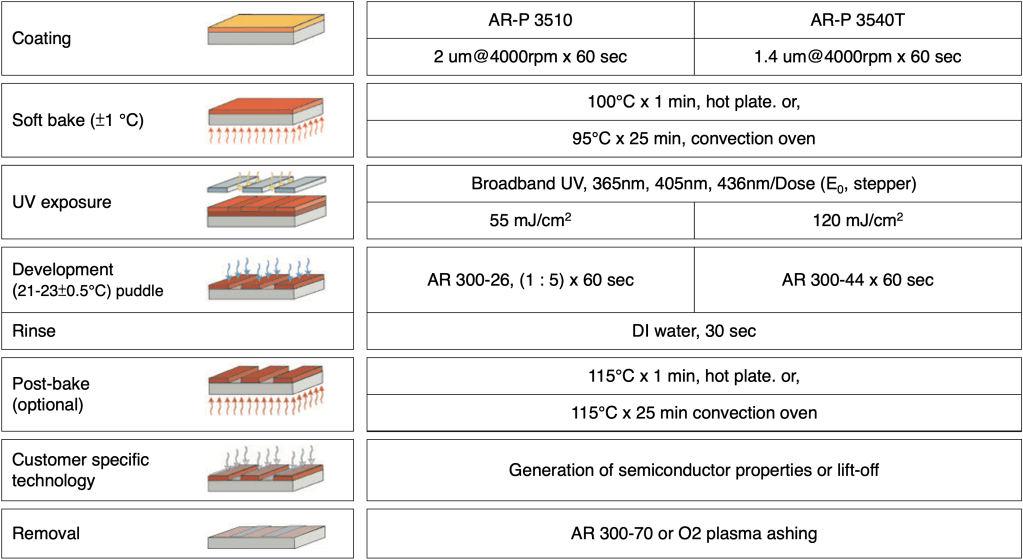

Process baseline 製程參數

This diagram shows exemplary process steps for AR-P 3500 series resists. All specifications are guideline values which must be adapted to own specific conditions. For further information on processing, 👉“ Detailed instructions for optimum processing of photoresists”. For recommendations on wastewater treatment and general safety instructions, 👉”General product information on Allresist photoresists”.

表列為AR-P 3500系列產品製程參數的範例。所有參數為參考值,使用者應依設備環境實際狀況加以調整。

Development recipe

| Resist | Developer | ||

| AR 300-26 | AR 300-35 | AR 300-40 series | |

| AR-P 3510 / AR-P 3540 | 1 : 5 | 1 : 1 | 300-47, 1 : 1 |

| AR-P 3510T / AR-P 3540T | 1 : 2 | pure | 300-44 |

Focus width AR-P 3540 T g-line stepper

| Ridge | DOF@230mJ | Dose range |

|---|---|---|

| 1.5 um | > 2.0 um | 110 – 260 mJ/cm2 |

| 1.0 um | > 1.5 um | 130 – 260 mJ/cm2 |

| 0.7 um | > 1.25 um | 160 – 250 mJ/cm2 |

| 0.5 um | > 1.0 um | 190 – 240 mJ/cm2 |

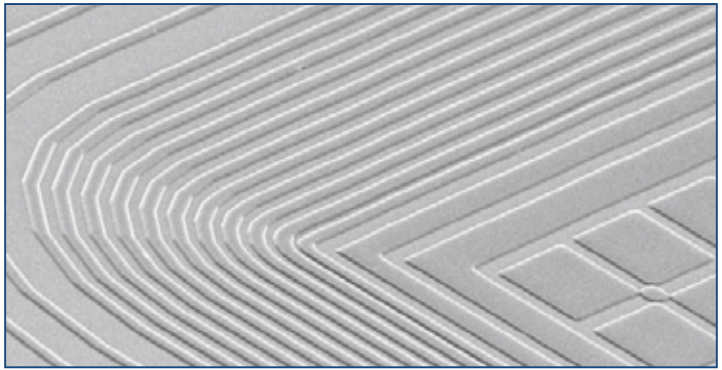

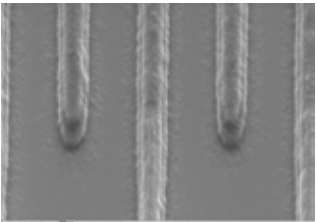

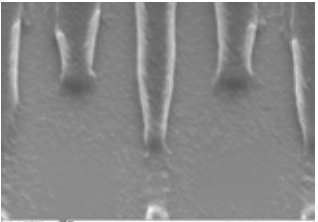

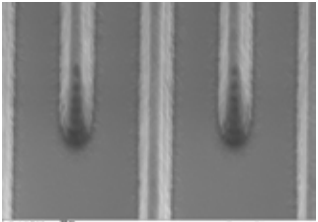

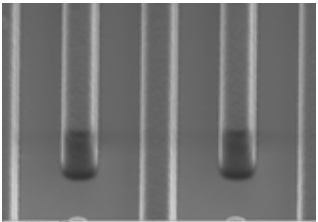

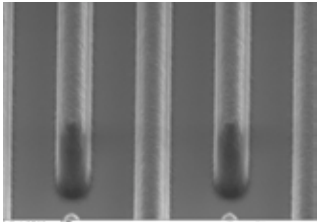

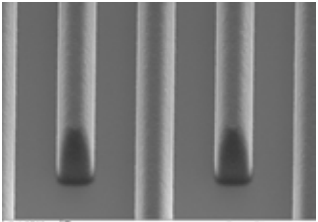

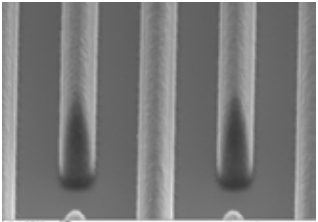

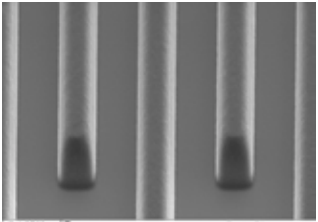

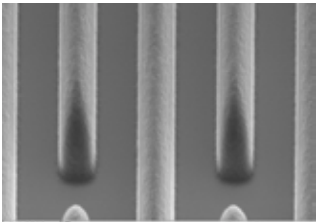

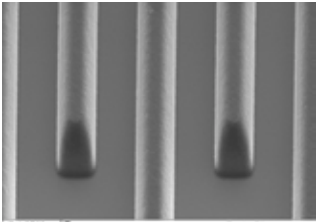

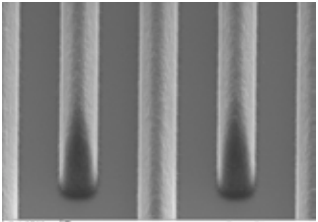

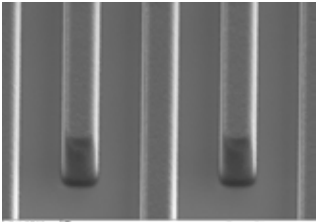

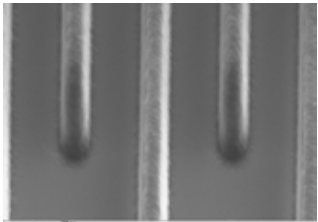

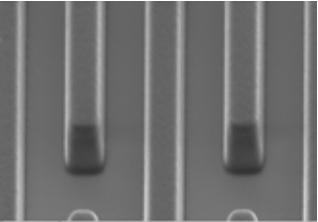

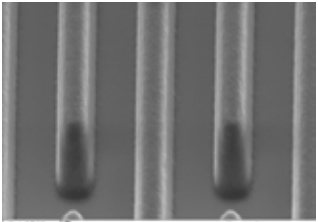

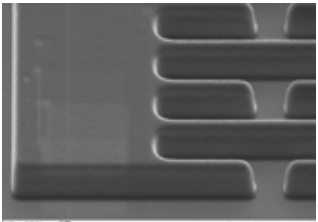

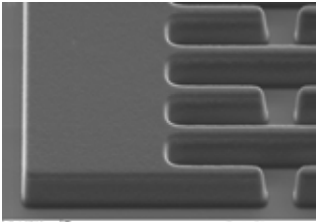

Resist structures

AR-P 3500

Film thickness 2 µm Resist structures 5 µm

…

Reference data 參考資料

Focus width

Film thickness 1.5 µm on Si-wafer, dose: 230 mJ/cm2

| Focus | 1.5 um L/S | 1.0 um L/S | 0.7 um L/S | 0.5 um L/S |

|---|---|---|---|---|

| – 1.0 |  |  |  |  |

| – 0.75 |  |  |  |  |

| – 0.5 |  |  |  |  |

| – 0.25 |  |  |  |  |

| 0.0 |  |  |  |  |

| + 0.25 |  |  |  |  |

| + 0.5 |  |  |  |  |

| + 0.75 |  |  |  |  |

exposure: g-line stepper (NA: 0.56; 0.75 s)

Development: AR 300-44, 60 s, 22 °C, puddle

Linearity

Film thickness 1.5 µm on Si-wafer, focus: 0.0

| Dose | 1.5 um L/S | 1.0 um L/S | 0.7 um L/S | 0.5 um L/S |

|---|---|---|---|---|

| 160 mJ |  |  |  | |

| 190 mJ |  |  |  |  |

| 210 mJ |  |  |  |  |

| 230 mJ |  |  |  |  |

Dark field erosion

Film thickness 1.5 µm on Si-wafer, focus: 0.0

| Dose | 1.5 um L/S | 1.0 um L/S | 0.7 um L/S | 0.5 um L/S |

|---|---|---|---|---|

| 190 mJ |  |  |  | |

| 210 mJ |  |  |  |  |

| 230 mJ |  |  |  |  |

exposure: g-line stepper (NA: 0.56; 0.75 s)

Development: AR 300-44, 60 s, 22 °C, puddle

…