AR 300-70 remover

For the stripping of photoresist and EBL resist

…

AR 300-70 Product brief 產品簡介

AR remover系列中,AR 300-70屬有機混合溶劑類型,適合去除高溫烘烤後的光阻及電子束微影阻劑。

產品說明如下:

…

Packing 產品包裝:

✅ 2.5 L/瓶

其它包裝可依客戶需求增加.

Shipping 出貨:

✅ 2 – 4 週: 徳國運出

❎ 1 週: 國內庫存

(目前暫無國內庫存)

…

Product Features 產品特性

- organic solvent mixture

混合有機溶劑 - storage at 10 – 22 °C for 6 months

儲存溫度 10 – 22 ℃ 可維持6個月的有效期限 - Main components : NEP (N-Ethyl-2-Pyrrolidone)

主要成份:N-乙基吡咯烷酮

…

Product properties 產品物性

| AR 300-70 | |

| Main components 主要成分 | NEP N-乙基吡咯烷酮 |

| Density at 20℃ (g/cm3) 密度 | 1.03 |

| Non-volatiles max. 非揮發成份(%) | 0.002 |

| Flash point (℃) 閃火點 | 98 |

| Filtration 過濾規格(um) | 0.2 |

| Storage 6 months 儲存溫度( ℃) | 10 – 22 |

| Photoresist hard bake up to 180℃ | — |

| Photoresist hard bake up to 200℃ | — |

| PMMA resist hard bake up to 200℃ | — |

| Copolymer EBL resist up to 210℃ | — |

| CSAR 62 EBL resist up to 200℃ | — |

| Novolac EBL resist up to 150℃ | — |

| Resist (PR & EBL) at lower hard bake | ✅ refer to detail conditions |

…

Dedicated remover for resist 適用阻劑

…

AR remover family introduction 系列阻劑去除劑說明

| Properties |

| AR 600-71 | AR 300-76 | AR 300-70 | AR 300-72 | AR 300-73 |

| Main components 主要成分 |

| dioxolane | DMG | NEP | NEP | TMAH |

| Density at 20℃ (g/cm3) |

| 1.02x | 1.08 | 1.03 | 1.03 | 1.00 |

| Non-volatiles max. 非揮發成份(%) |

| 0.002 |

| Flash point (℃) 閃火點 |

| 3 | 103 | 98 | 98 | — |

| Filtration 過濾規格(um) |

| 0.2 |

| Production status 生產排程1 |

| routine1 |

| Lead time 交期 |

| 2 – 4 週 |

| Product packing 產品包裝 |

| 2.5 L/瓶 |

| Storage 6 months 儲存溫度( ℃) |

| 10 – 18 | 10 -2 2 | 10 – 22 | 10 – 22 | 10 – 22 |

| Photoresist baking up to 180℃ |

| ✅ | ✅ |

| Photoresist baking up to 200℃ |

| ✅ |

| PMMA resist baking up to 200℃ |

| ✅ | ✅ |

| Copolymer EBL resist up to 210℃ |

| ✅ | ✅ |

| CSAR 62 EBL resist up to 200℃ |

| ✅ | ✅ |

| Novolac EBL resist up to 150℃ |

| ✅ | ✅ |

| Resist (PR & EBL) at lower baking2 |

| ✅1 | ✅ | ✅ | ✅ | ✅ |

| Remark: : |

| 1. routine: 固定排程生產,交期約2-4週。 2. 烘烤溫度低於150℃,細節請參考後面章節。 |

…

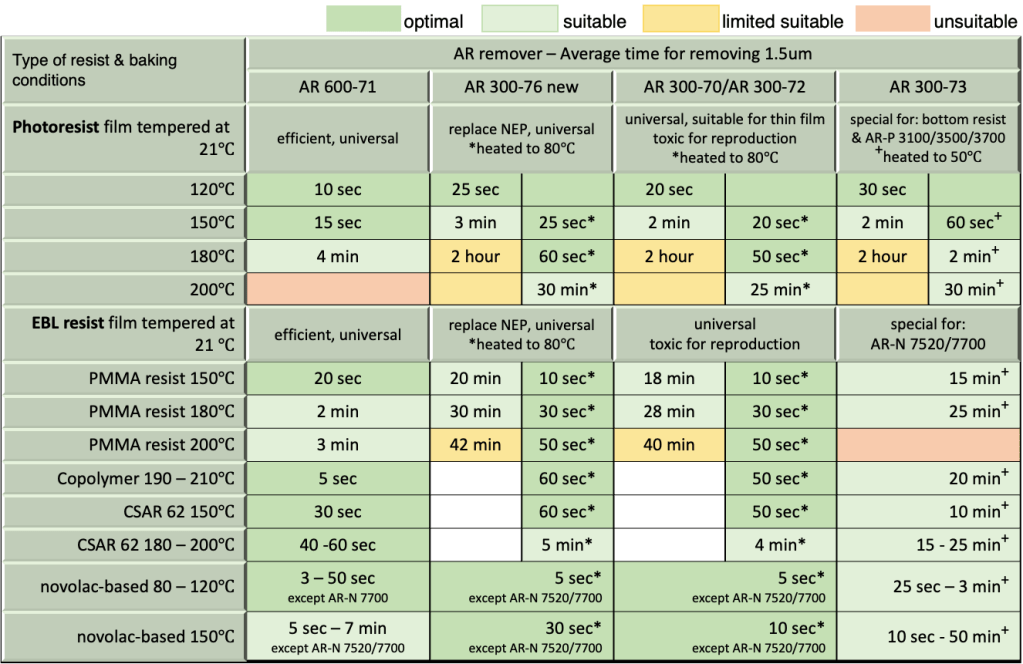

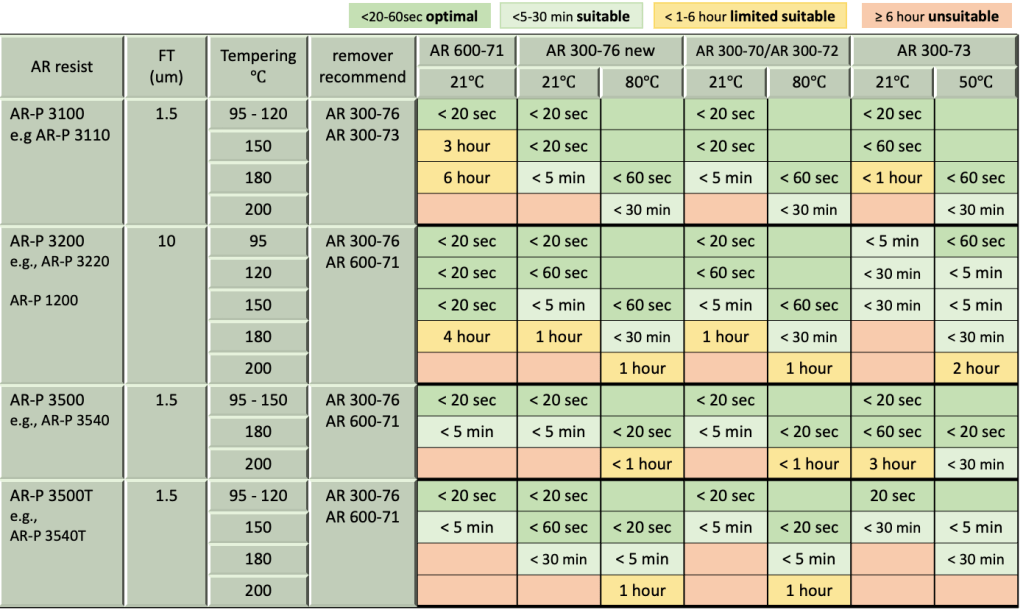

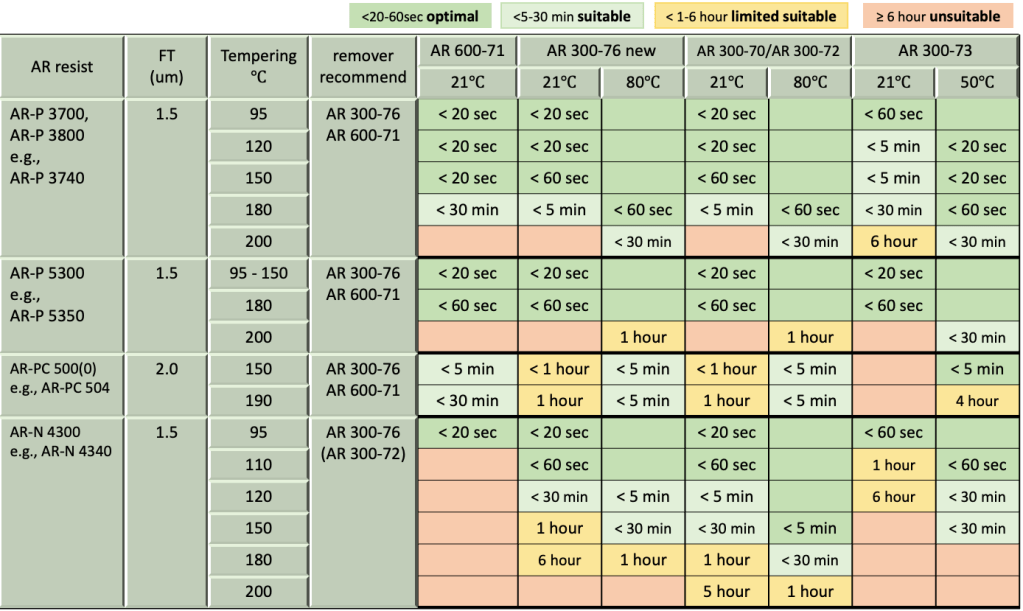

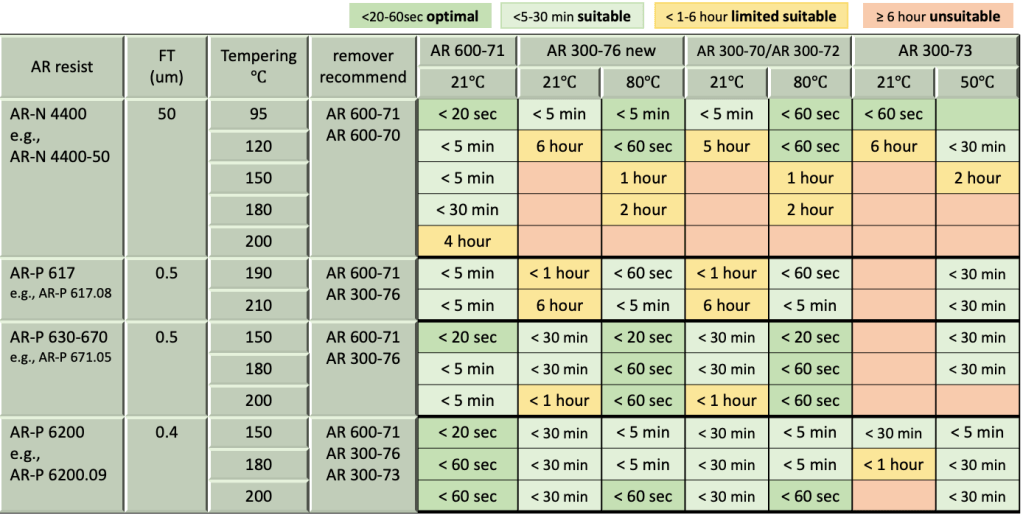

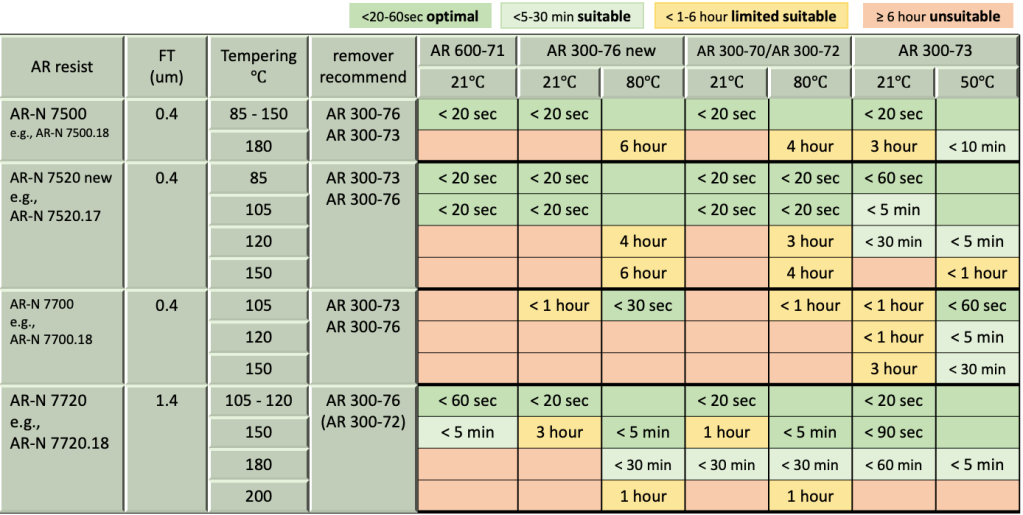

AR remover family – stripping baseline for baked resist

阻劑烘烤溫度與去除參數

Information on stripping process

Substrates coated with resist are exposed to the effect of the remover by immersion (puddle or dip). To reduce the dissolution time for tempered layers, removers AR 300-70, 300-72 and 300-76 may be heated to up to 80 °C, remover AR 300-73 to up to 50 °C or megasound may be helpful in this case. It is recommended to rinse off the remover with DI water, clean remover or with a suitable thinner. A stripping of very hard-baked layers (> 220 °C) with remover is hardly possible any more. In this case, oxidizing acids or oxygen plasma may be used for stripping. Further detailed remover specifications for a large variety of resists are listed on the following pages.

已塗有阻劑的基板浸泡於(puddle or dip)去除劑,將阻劑膜剝除. 為降低阻劑膜溶解時間, 去除劑AR 300-70, AR 300-72及AR 300-76可加熱至80℃; AR 300-73可加熱至50℃. 或施以兆聲波(megasonic)輔助清洗.

去除程序後,建議以DI water或稀釋液以清洗殘留去除液.

對於經過大於220℃高溫硬烤的阻劑,去除劑基苯上已很難作用,可使用酸性氧化或電漿去除.

更詳細及適用範圍,請參考下頁.

…

Baseline of remover family vs AR resist

The average times required for removal as listed under “properties” are divided into time clusters (< 20 s, < 60 s …) for better orientation. Remover recommendations generally apply to the commonly used tempering at 150 °C and 180 °C. The recommendation for remover AR 300-72 is indicated in brackets, since this remover is highly effective, but also classified as toxic for reproduction and thus not prioritized by Allresist. As replacement, we recommend the equivalent removers AR 300-76 and 600-71.

去除劑的建議是以阻劑一般加熱在150℃及180℃為基準。

AR 300-72歸類於毒性回收再製物質,不建議使用. 可以AR 300-76及AR 600-71取代.

…