AR-N 7520 series standard negative e-beam lithography resist

High resolution for mix & match-processes, high-precision edges

…

Product brief 產品簡介

AR-N 7520系列, 為負型電子束微影阻劑 (negative tone EBL resist). 可以電子束及紫外光曝光(deep UV, I line), 適合於半導體混搭製程(mix & match).

與新品(AR-N 7520 new)比較, AR-N 7520系列需要較高的曝光能量,優點是可獲得較為垂直圖案. 產品系列目前有:

AR-N 7520.073

AR-N 7520.18

…

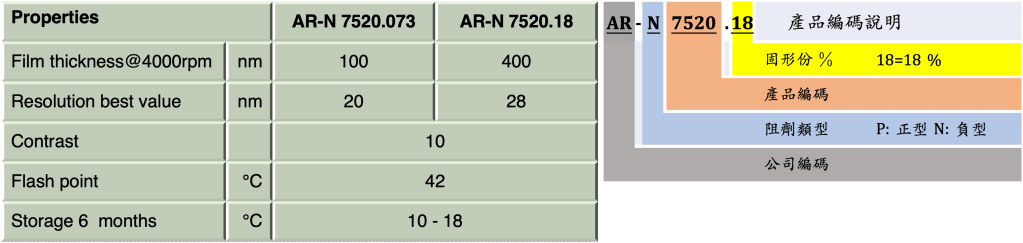

Product code & comparison 產品比較及編碼說明:

…

Packing 產品包裝:

✅ 100 ml /瓶

✅ 250 ml/瓶

✅ 1 L /瓶

其它包裝可依客戶需求增加.

Shipping 出貨:

✅ 2 – 4 週. 徳國運出

❎ 1 週. 國內庫存

(本品項暫時無庫存)

…

Product Features 產品特性

- e-beam, deep UV, i-line

曝光源可為電子束, 深紫外線, 紫外線(i-line) - very high contrast, excellent transfer of structures, high-precision edges

高對比, 良好的圖案轉移,結構邊緣精確 - mix & match processes between e-beam and UV exposure 248-365 nm

適合電子束與紫外線 (248 – 365 nm)的混搭製程 - •highest resolution, very process-stable (no CAR)

非化學放大型,但解析度高,製程穩定

- plasma etching resistant, temperature stable up to 140 °C

耐乾蝕刻, 高溫穩性定達140℃ - novolac, organic cross-linking agent

主要成份含酚醛樹酯, 有機物架橋劑等 - safer solvent PGMEA

溶劑使用較安全的丙二醇甲醚醋酸酯

…

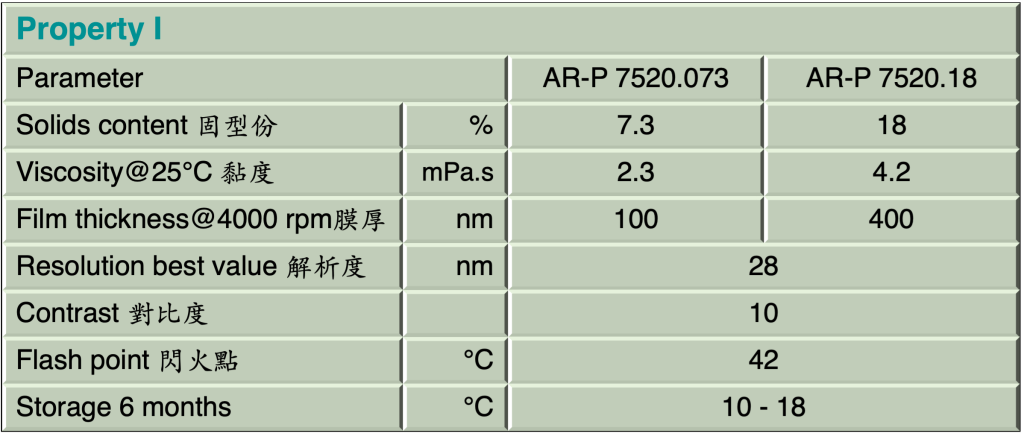

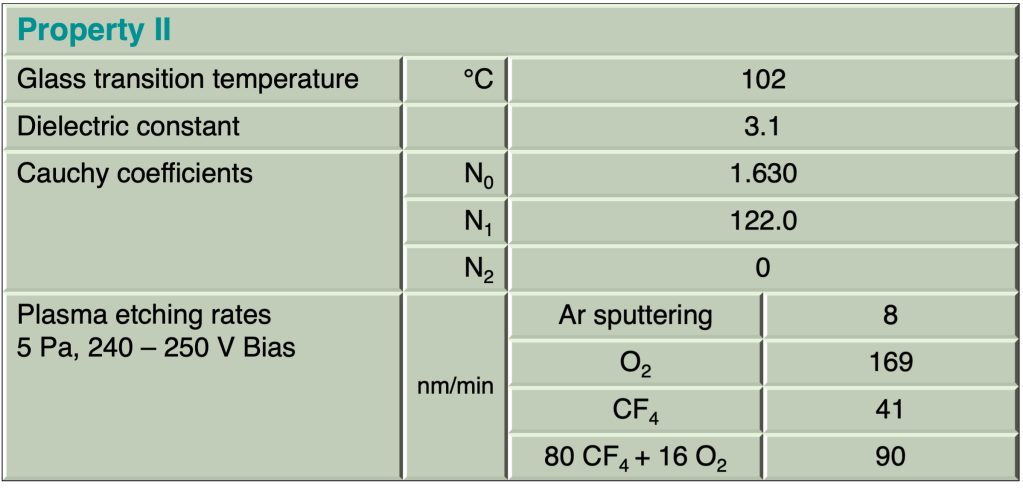

Product Properties 產品物性

…

Spin curve 塗佈曲線

…

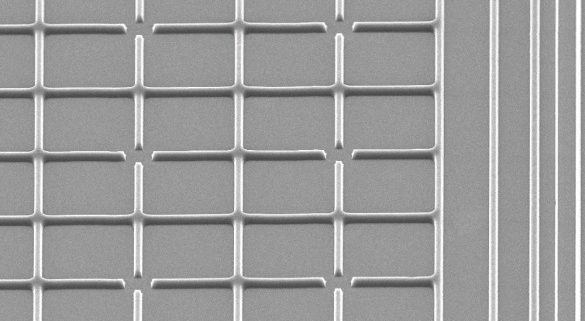

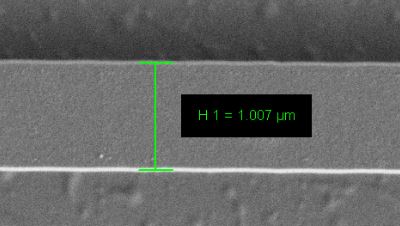

Structure resolution

400 nm lines with AR-N 7520.073

Resist structures

1 μm line with high-precision edges, AR-N 7520.18, ft:340 nm, 1,400 μC/cm², 100 kV

Process parameters

| Substrate | 4″ Si wafer |

| Soft bake | 85℃x90sec, hot plate |

| Exposure | Raith Pioneer, 30kV |

| Development | AR 300-47, 4:1, 60sec 22℃ |

…

Process baseline 製程參數

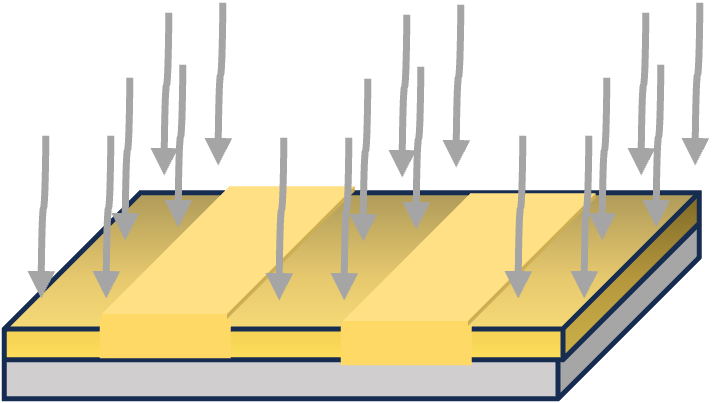

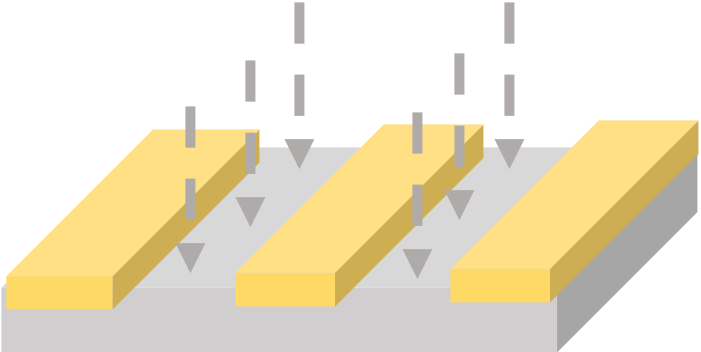

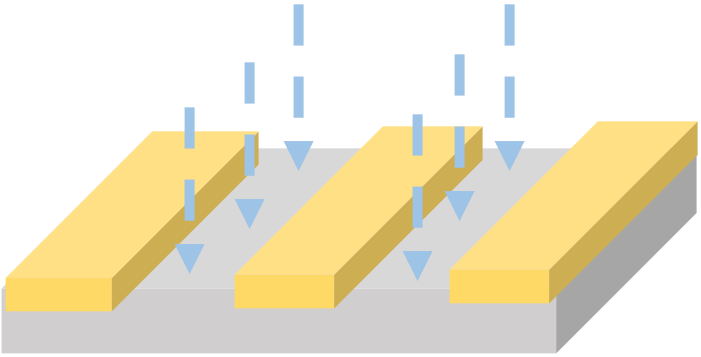

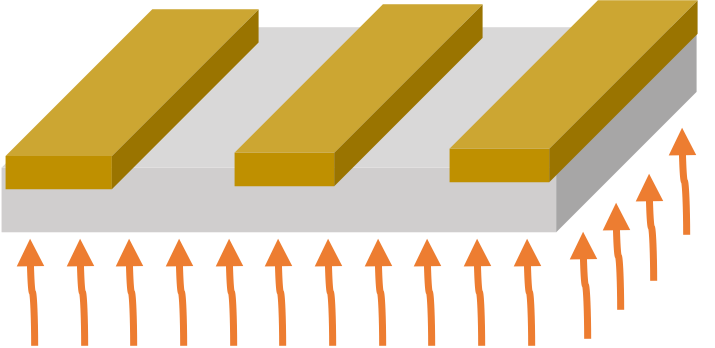

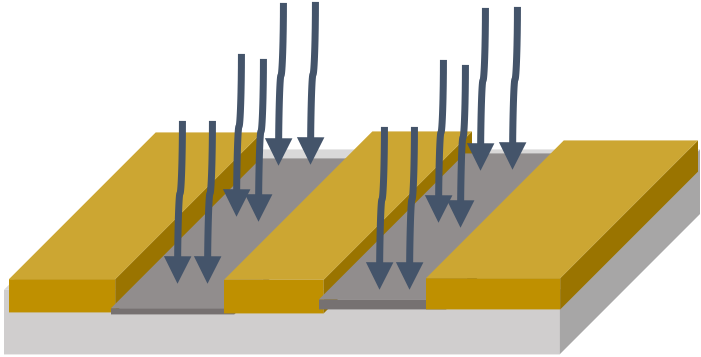

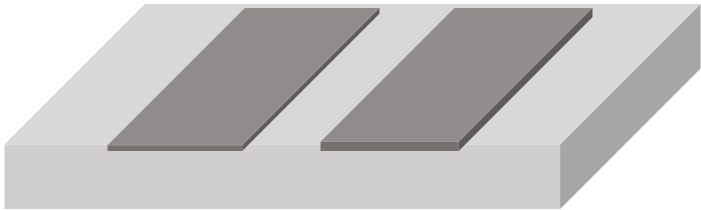

This diagram shows exemplary process steps for AR-N 7520 resists. All specifications are guideline values which have

to be adapted to own specific conditions. For further information on processing, 👉“Detailed instructions for optimum processing of e-beam resists”. For recommendations on waste water treatment and general safety instructions,

👉”General product information on Allresist e-beam resists”.

表列為AR-N 7520阻劑產品製程參數的範例. 所有參數為參考值,使用者應依設備環境實際狀況加以調整

| Process | AR-N 7520.18 | AR-N 7520.073 |

|---|---|---|

Coating | 400nm @4000 rpm x 60sec | 100nm @4000 rpm x 60 sec |

soft-bake (±1℃) | 85℃ x 2 min/hot plate, or 85℃ x 30 min/convection oven | |

| e-Beam exposure dose (E0)  | Raith Pioneer, 30kV 500 uC/cm2 100 nm line & space | Raith Pioneer, 30kV 300 uC/cm2 100 nm line & space |

| Development 21-23℃ puddle  | AR 300-47, 4:1, 90 sec | AR 300-47, 4:1, 50 sec |

Rinse | DI water, 30 sec | |

| Post-bake (optional)  | 85 ℃ x 1 min hot plate, or 85 ℃ x 25 min convection oven for enhanced plasma etching resistance | |

| Customer specific process  | Generation of semiconductor properties | |

Removal | AR 300-73, or O2 plasma ashing | |

…

Development recommendation

…

Process instruction 製程說明

These resists are predestined for e-beam exposure, but also suitable for UV exposure. Mix & match processes are possible if both exposure methods are carefully coordinated. During e-beam exposure, the resist works in a negative mode. (For details on Mix & Match, see AR-N 7520 new). Due to their composition, resists AR-N 7520 are approximately 8 x more insensitive than resists of the series AR-N 7520 new. The required higher dose predestines these resists for the production of very precise structural edges, since due to the high electron density edges are perfectly reproduced. For the very high imaging quality however, longer writing times have to be accepted.

The developer dilution should be adjusted with DI water such that the development time is in a range between 20 s and 120 s. By dilution of the developer, contrast and development rate can be influenced to a large degree. A stronger dilution results in an increased contrast and a reduced development rate.

AR-N 7520系列是設計為電子束微影阻劑,但也適合於紫外線曝光. 兩種曝光參數經適當調配,可用於半導體混搭製程(mix & match).阻劑在電子束曝光下為負型模式.

(混搭製程細節,請參考產品AR-N 7520new)

由於配方成份不同,AR-N 7520的敏感度比AR-N 7520new低,差異達8倍. 由於需要的曝光劑量高,此產品適合生產精確的圖案邊緣. 但所需的時間同時也較長.

顯影劑濃度視需要以純水調整,建議的顯影時間,溫度為20 – 120 sec.

稀釋顯影劑對對比度及顯影率影響很大. 稀釋過度會降低對比度及顯影速率.

…