Negative e-Beam Resist AR-N 7520-new series

High Resolution EBL Resist for Mix & Match in Semiconductor Process

…

Product brief 產品簡介

AR-N 7520-new系列, 為負型電子束微影阻劑 (negative tone EBL resist). 可以電子束及紫外光曝光(deep UV, I line), 適合於半導體混搭製程(mix & match). 產品系列目前有:

AR-N 7520.07 new

AR-N 7520.11 new

AR-N 7520.17 new

…

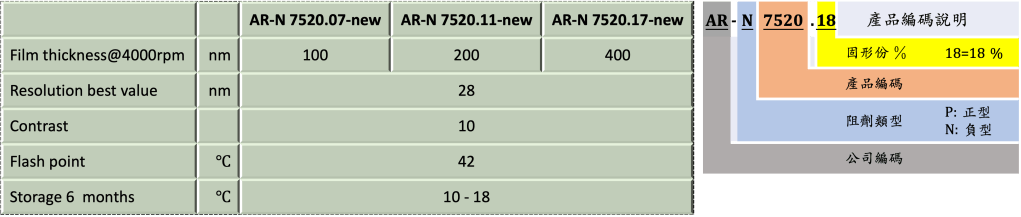

Product series & Code 產品比較及編碼說明:

…

Packing 產品包裝:

✅ 100 ml /瓶

✅ 250 ml/瓶

✅ 1 L /瓶

其它包裝可依客戶需求增加.

Shipping 出貨:

✅ 2 – 4 週. 徳國運出

❎ 1 週. 國內出貨

(本品項暫時無國內庫存)

…

Product Features 產品特性

- e-beam, deep UV, i-line (formerly SX AR-N 7520/4)

曝光源可為電子束, 深紫外線, 紫外線(i-line). (開發時期型號為SX AR-N 7520/4) - short writing times, very high contrast

轉寫時間短, 對比度高 - mix & match processes between e-beam and UV exposure 248-365 nm, negative in the UV range

適合電子束與紫外線 (248 – 365 nm)的混搭製程, 紫外線曝光下為負型模式 - highest resolution, very process-stable (no CAR)

非化學放大型,但解析度高,製程穩定

- plasma etching resistant, temperature stable up to 140 °C

耐乾蝕刻, 高溫穩性定達140℃ - novolac, organic cross-linking agent

主要成份含酚醛樹酯, 有機物架橋劑等 - safer solvent PGMEA

溶劑使用較安全的丙二醇甲醚醋酸酯

…

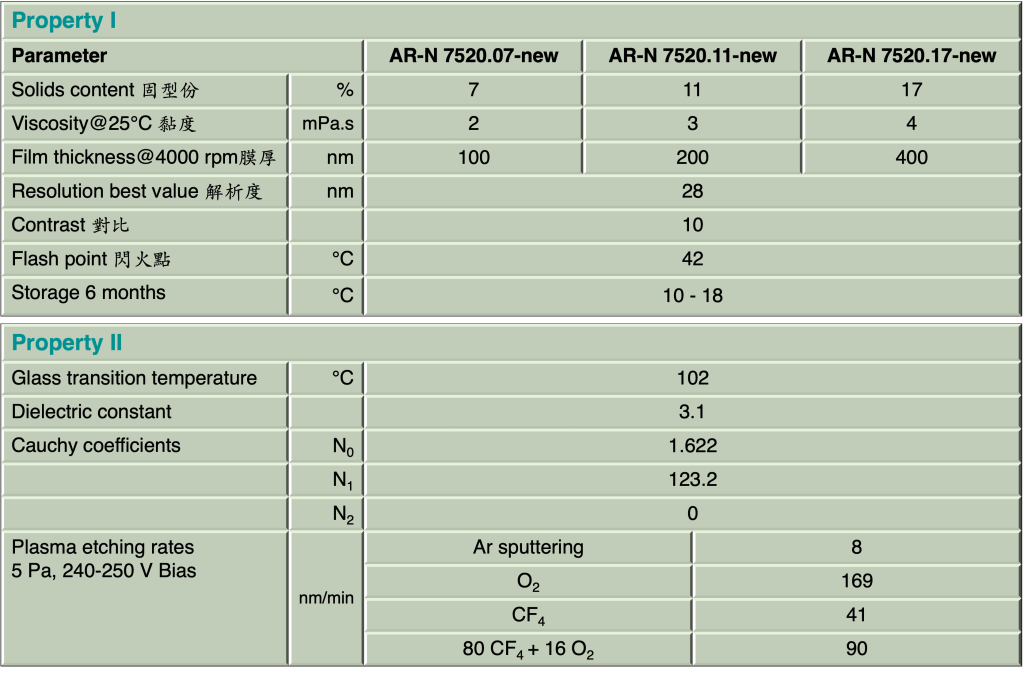

Product Properties 產品物性

…

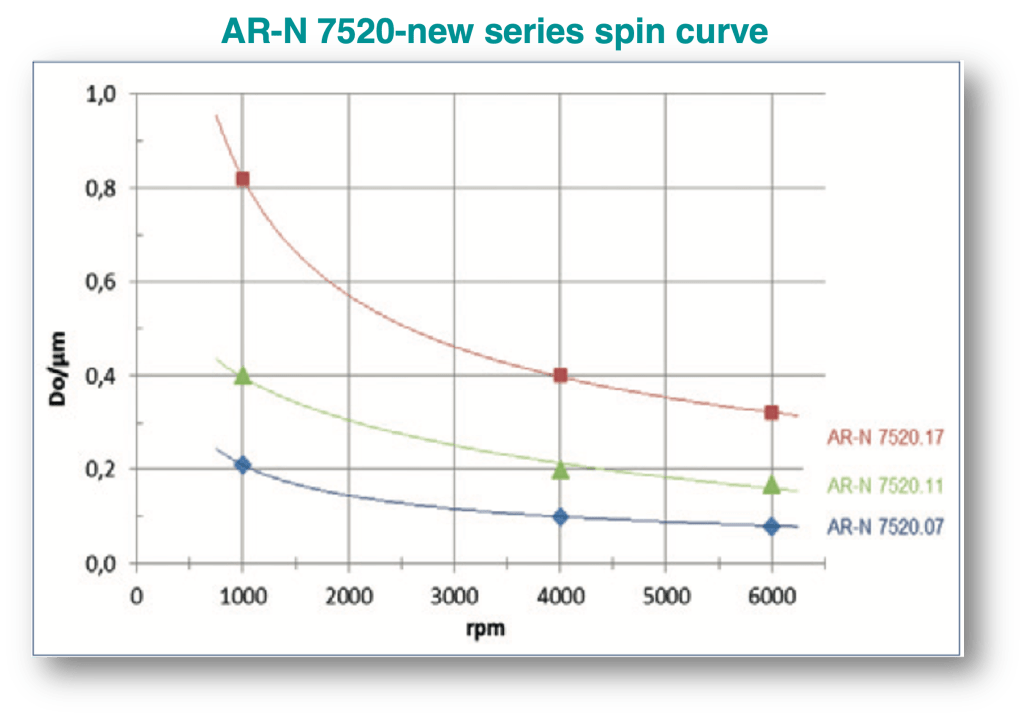

Spin curve 塗佈曲線

…

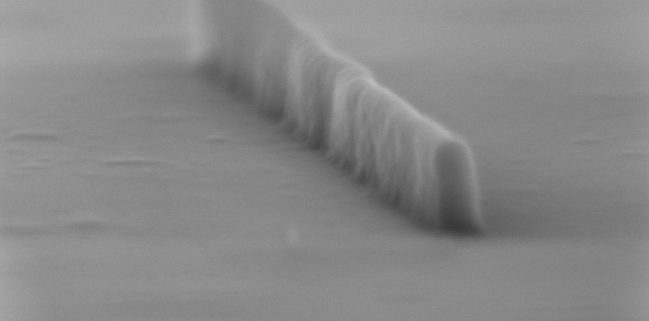

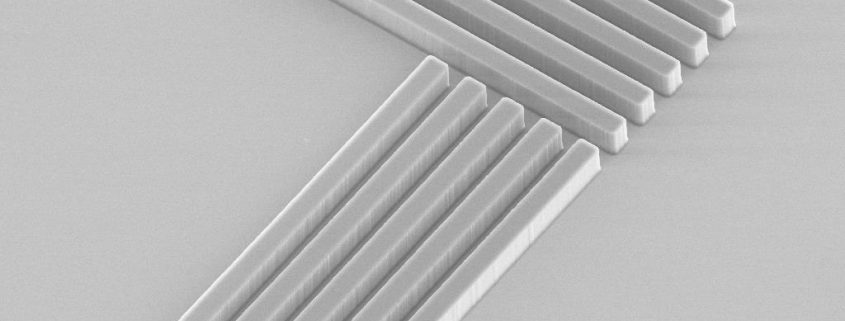

Structure resolution

AR-N 7520.07 new: 30-nm lines at a film thickness of 90 nm

Resist structures

AR-N 7520.17 new: 400- and 600-nm lines, film thickness 400 nm

Process parameters

| Substrate | 4″ Si wafer |

| Soft bake | 85℃x90sec, hot plate |

| Exposure | Raith Pioneer, 30kV |

| Development | AR 300-47, 60sec 22℃ |

…

Process baseline 製程參數

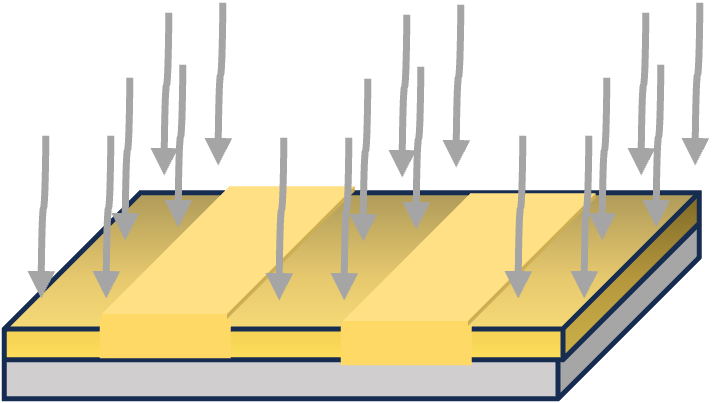

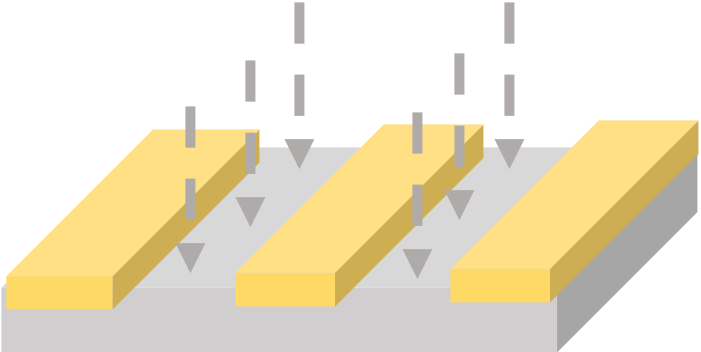

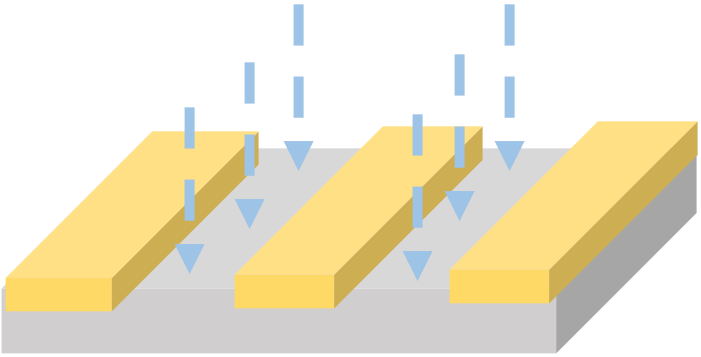

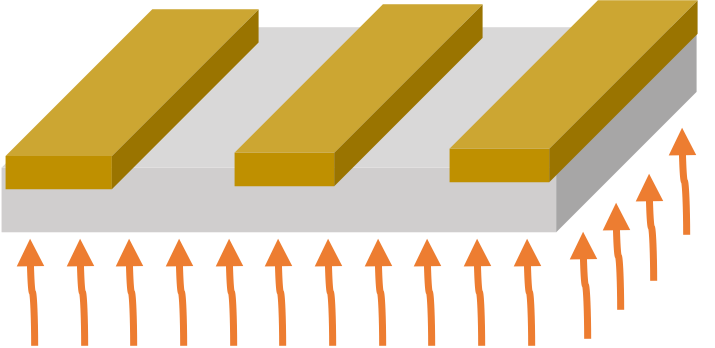

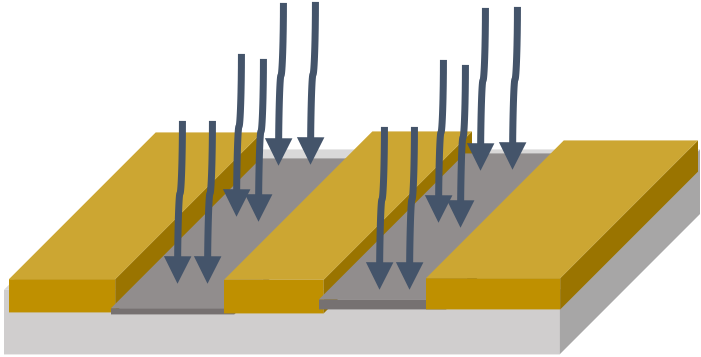

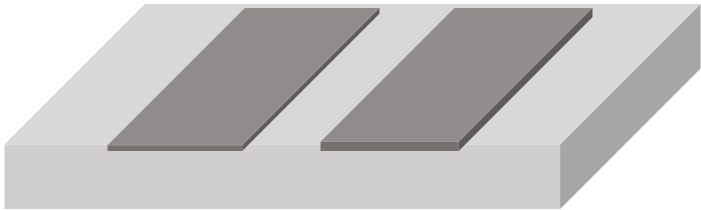

This diagram shows exemplary process steps for resists of AR-N 7520-new series. All specifications are guideline values which must be adapted to own specific conditions. For further information on processing, 👉 “Detailed instructions for optimum processing of e-beam resists”. For recommendations on wastewater treatment and general safety instructions, 👉”General product information on Allresist e-beam resists”.

表列為AR-N 7520 new阻劑產品製程參數的範例. 所有參數為參考值,使用者應依設備環境實際狀況加以調整

| Process | AR-N 7520.17 new | AR-N 7520.07 new |

|---|---|---|

Coating | 400nm@4000 rpm x 60sec | 100nm@4000 rpm x 60 sec |

soft-bake (±1℃) | 85℃ x 1 min/hot plate, or 85℃ x 30 min/convection oven | 85℃ x 1 min/hot plate, or 85℃ x 30 min/convection oven |

| e-Beam exposure dose (E0)  | Raith Pioneer, 30kV 30 uC/cm2 ,100 nm line & space | Raith Pioneer, 30kV 30 uC/cm2 ,100 nm line & space |

| Development 21-23℃ puddle  | AR 300-46, 90 sec | AR 300-47, 50 sec |

Rinse | DI water, 30 sec | DI water, 30 sec |

| Post-bake (optional)  | 85 ℃ x 1 min hot plate, or 85 ℃ x 25 min convection oven for enhanced plasma etching resistance | 85 ℃ x 1 min hot plate, or 85 ℃ x 25 min convection oven for enhanced plasma etching resistance |

| Customer specific process  | Generation of semiconductor properties | Generation of semiconductor properties |

Removal | AR 300-73, or O2 plasma ashing | AR 300-73, or O2 plasma ashing |

…

Development recommendation

…

Process instruction 製程說明

These resists are predestined for e-beam exposure, but also suitable for UV exposure. Mix & match processes are possible, if both exposure methods are carefully coordinated. During e-beam exposure, the resist works in a negative mode.

The resist works also in a negative mode with deep UV (248-270 nm) or mid-UV (290-365) exposure. If a further tempering step (85 °C, 2 min hot plate) is added after image-wise exposure, the sensitivity can be slightly enhanced.

The developer dilution should be adjusted with DI water such that the development time is in a range between 20 s and 120 s. By dilution of the developer, contrast and development rate can be influenced to a large degree. A stronger dilution results in an increased contrast and a reduced development rate.

AR-N 7520-new系列是設計為電子束微影阻劑,但也適合於紫外線曝光. 兩種曝光參數經適當調配,可用於半導體混搭製程(mix & match).阻劑在電子束曝光下為負型模式.

在深紫外線(248-270 nm)及中紫外線(290-365 nm)下曝光亦為負型模式. 曝後烤(85℃ x 2 min, 熱板)可些微增加敏感度.

顯影劑濃度視需要以純水調整,建議的顯影時間為 20 – 120 sec.

稀釋顯影劑對對比度及顯影率影響很大. 過度稀釋會降低對比度及顯影速率.

…