Conductive Coating AR-PC 5094.02 (Electra 92)

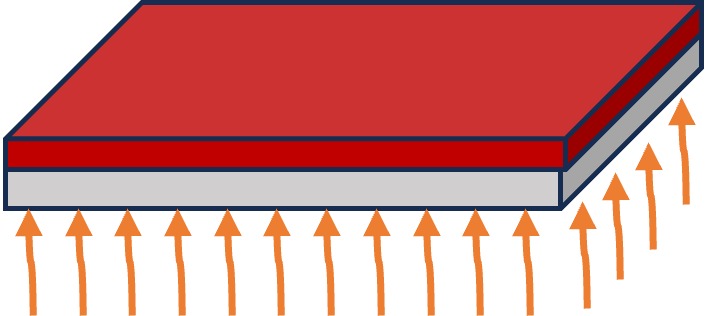

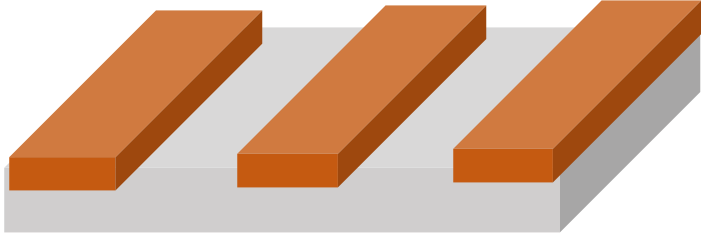

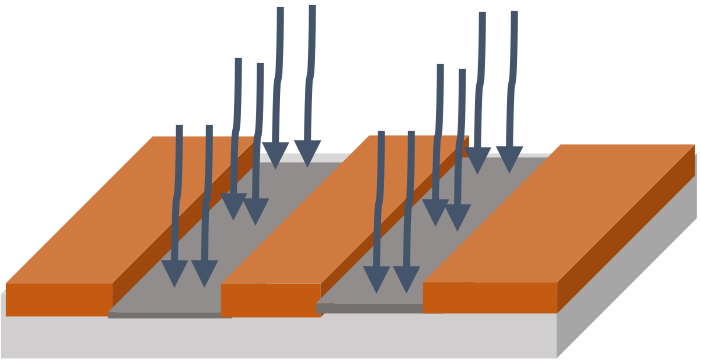

Top layer dissipation of electron beam charges on insulating substrate

A new product for both polymer and novolac-based EBL resist applications

…

Electra 92 Product Brief 產品說明

Electra 92 應用於電子束微影或顯微鏡分析,於絕緣基板上塗佈導電層,使電子束曝光時電荷得以逸散.由於產品持續不斷優化,從溶劑改良到產品穩定性,塗佈品質等不斷改善,目前最新通用型版本的產品編號為:AR-PC 5094.02

產品適用於各類型阻劑,例如CSAR 62 (複合高分子copolymer);Medusa 84 SiH (HSQ),酚醛樹酯(novolac),PMMA等,涵蓋大部份阻劑類型,但不適用CAR阻劑(化學放大型)註1 。

與舊版本產品比較,及其生產狀況,請參考與舊版產品比較。

註1:適用於CAR type的版本目前開發中,待完成後發表。

…

AR-PC 5092.02 packing & shipping

Packing 產品包裝:

✅ 100 ml/瓶

✅ 250 ml/瓶

✅ 1 L/瓶

其它包裝可依客戶需求增加.

Shipping 出貨:

✅ 2 – 4 週: 徳國運出

❎ 1 週: 國內庫存

(目前暫無國內庫存)

…

AR-PC 5094.02 Features 產品特性

- as a protective coating, this resist is not sensitive to light / radiation

此導電保護塗佈材料對光/輻射不感應 - thin, conductive layers for the dissipation of charges during electron exposure

塗佈形成導電薄膜使電子束曝光時,電荷得以逸散 - for coating on all AR e-beam resists, e.g. CSAR 62, Medusa 84 SiH, except CAR resists

適用於各類型阻劑,例如: CSAR 62, HSQ等。但不適用於化學放大型阻劑

- Improved properties compared to AR-PC 5092.02

由前版本持續優化改良 - easy removal with water after exposure

曝光後可輕易以水去除 - polyaniline-derivative dissolved in water

主要成分為溶於水的聚苯胺衍生物

…

Product properties 產品物性

| AR-PC 5094.02 Property I | ||

| Parameter | AR-PC 5094.02 | |

| Solid content 固型份 | % | 2 |

| Viscosity@25℃ 黏度 | mPas | 1 |

| Film thickness@4000 rpm 膜厚 | nm | 42 |

| Film thickness@1000 rpm膜厚 | nm | 100 |

| Resolution / Contrast | nm/– | – – |

| Storage temperature* 儲存溫度 | ℃ | 8 – 12 |

| * Product is guaranteed 6 months shelf life from the data of sale if stored correctly. 在正確的儲存條件下,產品保證的有效期為銷售日起6個月. * Product can also be used without guarantee until the date indicated on the label. 在無提供保證的情況下,產品可使用至標籤上所示的有效期. | ||

| AR-PC 5092.02 Property II | ||

| Conductivity (@ 60nm FT) | S/m | 1.2 |

…

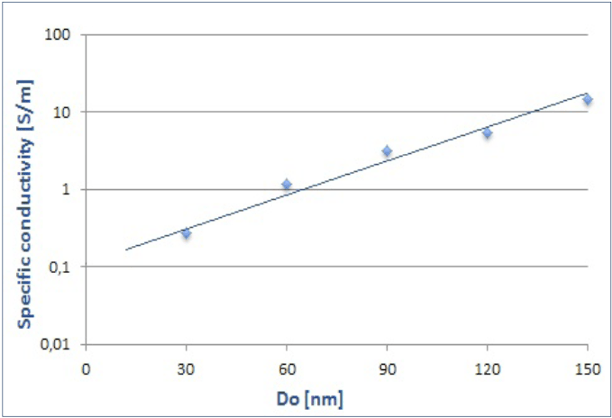

Conductivity 導電度

Conductivity measurements of AR-PC 5094.02 layers obtained after spin

deposition. For thinner films, the resistance increases and the conductivity decreases.

AR-PC 5094.02的導電度於塗佈後測得. 膜厚越低,其導電阻抗增加而導電度下降. 如圖.

…

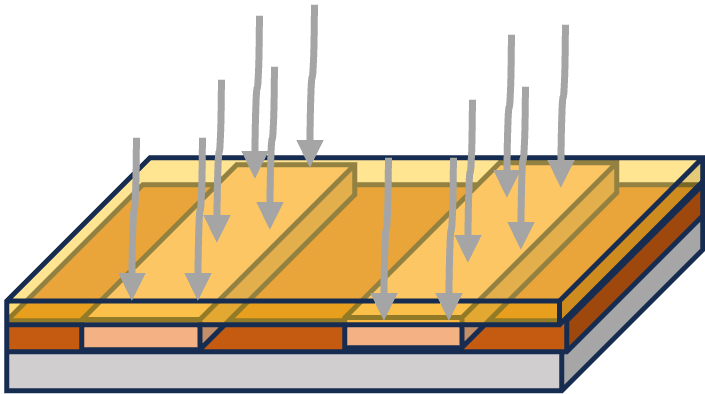

Process baseline 製程參數

| Conductive coating of PMMA resist Thsi diagram shows exemplary process steps Electra92 (AR-PC 5094.02) and PMMA resist AR-P 664.04. All specifications are guideline values which have to be adapted to own specific conditions. 本製程參數是以 AR-PC 5094.02 (Electra 92) 與AR-P 664.04 (PMMA resist)為範例. 建議使用者依實際材料組合調整參數. | |||

| 1st Coating |  | AR-P 662.04 on insulating substrate (quartz, glass, GaAs) 140nm@4000rpm x 60sec | |

| 1st soft bake (±1℃) |  | 150 ℃ x 2 min hot plate, or 150 ℃ x 30 min convection oven | |

| 2nd Coating conductive layer |  | AR-PC 5094.02 60nm@2000rpm x 60sec | |

| 2nd soft bake (±1℃) |  | 90°C x 2min hot plate or 85°C x 25min convection oven | |

| e-Beam exposure |  | ZBA 21, 20 kV Exposure dose (E0): 110 uC/cm2 (AR-P 662.04, 140nm) | |

| Removal Conductive layer |  | AR-PC 5094.02 DI water, 60sec | |

| Development puddle (21-23 ± 0.5℃) |  | Resist: AR-P 662.04 Developer: AR 600-56 x 2min Stopper: AR 600-60 x 30sec | |

| Post-bake (optional) |  | 130°C x 1min hot plate or 130°C x 25min convection oven for slightly enhanced plasma etching stability | |

| User specific process |  | Generation of e.g. semiconductor properties, etching, sputtering…. | |

| Removal |  | AR 600-71 or O2 plasma ashing | |

| Process hints The conductivity may be varied by adjusting the thickness with different rotational speeds. Thicker layers of 90 nm thus have a 2.5 times higher conductivity as compared to 60 nm thick layers. For the build-up of an even conductive layer, the substrate should be wetted with the resist solution before the spin process is started. 導電度可依導電層厚度加以調節. 90nm厚的導電層比60nm厚其導電度高約2.5倍. 導電層塗佈前先以阻劑的溶劑濕潤基板可獲得較均勻的厚度. | |||

…

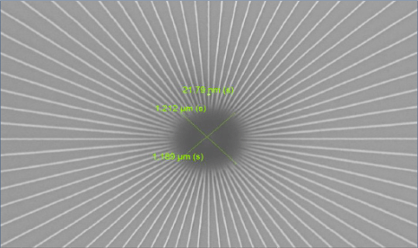

Medusa 84 SiH (HSQ) on quartz with AR-PC 5094.02 導電塗層與HSQ搭配範例

Siemens star written on quartz with the new conductive coating Electra 92 (AR-PC 5094.02) spun on to prevent charge build-up. This variant of Electra 92, specially developed for HSQ, has excellent coating and adhesion properties. © B. Drent, AMOLF NanoLab Amsterdam

Electra 92 (AR-PC 5094.02)為新版導電塗層,對HSQ有良好塗佈特性及黏著度。

下圖為Medusa 84 SiH搭配新版Electra 92於石英基板寫出西門子星標的範例。

…

Electra 92 product comparison 產品比較

| Properties | AR-PC 5090.02 | AR-PC 5091.02 | AR-PC 5092.02 | AR-PC 5094.02 | |

| Solid content (固型份) | % | 2 | 2 | 2 | 2 |

| Viscosity (黏度) | mPas | 1 | 1 | 1 | 1 |

| Thickness (厚度) vs Spin speed (轉速) | nm rpm | 42 – 100 @ 4000 – 1000 | 31 – 80 @ 4000 – 1000 | 42 – 100 @ 4000 – 1000 | 42 – 100 @ 4000 – 1000 |

| Specific conductivity (@60nm FT)導電度 | S/m | ~100 | ~100 | ~100 | 1.2 |

| Conductive polymer (高分子類型) | polyaniline-derivative | polyaniline-derivative | polyaniline-derivative | polyaniline-derivative | |

| Solvent (使用溶劑) | Water & IPA | Water & IPA | Water | Water | |

| Resist compatibilities (適用阻劑類型) | non-novolac PMMA co-polymer (CSAR 62) HSQ (Medusa 82) | novolac base resist | (universal type) novolac base resist PMMA co-polymer (CSAR 62) HSQ (Medusa 82) and others | universal except CAR* | |

| Production status (供應情況) | discontinue | discontinue | phase out (on-demand)* | routine | |

| Remark 說明 | *1 適用於化學放大型(CAR resist)的版本開發中,將於近日發表。 *2 on-demand為無固定排程,需預定生產。可能會有最小數量,或等待生產批次。 | ||||

…