AR-BR 5400 series resist for 2-layer lift-off system

For optical transparent structure& thermal stable up to 250℃

…

AR-BR 5400 series product brief 產品說明

AR-BR 5400系列產品其材料在波長270nm至紅外線(IR)為透明,可作為雙層浮剝離製程(2-layer lift-off)的底層阻劑; 還可作為耐溫的透明結構.

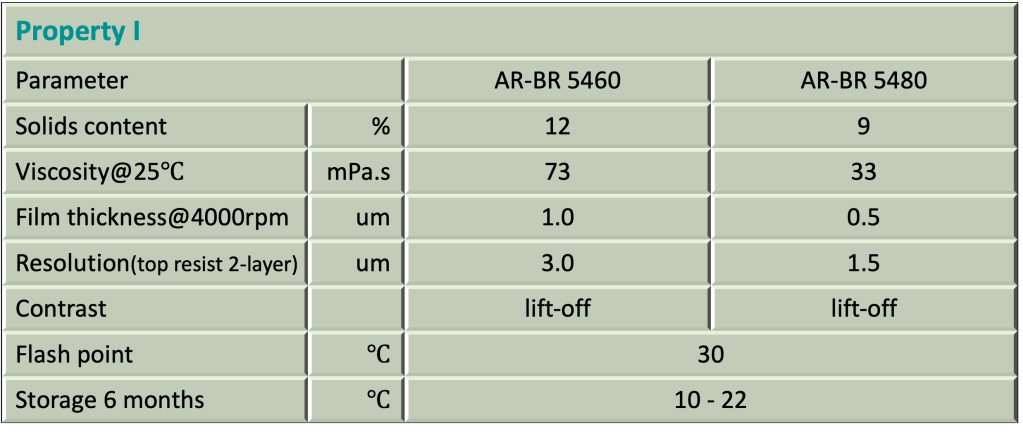

產品編號及基本資料如下:

| Basic properties |

| AR-BR 5460 | AR-BR 5480 |

| Film thickness@4000rpm 厚度 (um) |

| 1.0 | 0.5 |

| Resolution to resist 2L 解析度 (um) |

| 3 | 1.5 |

| Flash point 閃火點 ℃ |

| 30 | 30 |

| Production status1 |

| routine1 | routine |

| Product packing 產品包裝 (ml/瓶) |

| 100 / 250 / 1,000 | 100 / 250 / 1,000 |

| Lead time 交期 (週) |

| 2 – 4 | 2 – 4 |

| Storage 6 months 6個月有效期限保存溫度 (℃) |

| 10 – 18 | 10 – 18 |

| 1. Production status: on-demand:產品無固定排程生產,需先詢問價格。可能會有最小量訂單,或需等待批次生產排程。 Routine: 產品固定排程生產,交貨期約2-4週。 |

…

Packing & shipping 產品包裝與出貨

packing 產品包裝

✅ 100 ml/瓶

✅ 250 ml/瓶

✅ 1 L/瓶

其它包裝可依需求研擬增加

shipping 產品出貨

✅ 2 – 4 週。德國運出。

❎ 1 週。 國內庫存。

(本產品暫無國內庫存)

…

Product features 產品特性

- bottom resist not light sensitivity

材料不感光,做為底層阻劑或結構材。 - broadband UV, i-line, g-line for top resist

上層光阻曝光波長為寬頻紫外線, i-line, g-line - for lift-off structures

可作為懸浮剝離應用 - for optically transparent structures from 270 nm to IR with thermally stable structures up to 250 °C

可作為耐溫的透明結構 (波長270nm至紅外線為透明) - aqueous-alkaline development

顯影系統為鹼性水溶液 - temperature-stable up to 140 °C (with AR-P 3500)

與光阻AR-P 3500系列搭配為雙層製程,製程耐溫為140℃ - 5400 copolymer methyl methacrylate/methacrylic acid

聚合物成份為甲基丙烯酸甲酯(MMA)及甲基丙烯酸(MA)共聚物 - 3- safer solvent PM (5400), PGMEA (3500, 4340)

製程阻劑皆使用較安全溶劑:丙二醇甲醚(AR-BR 5400)

丙二醇單甲醚醋酸酯(AR-P3400, AR-N 4340)

…

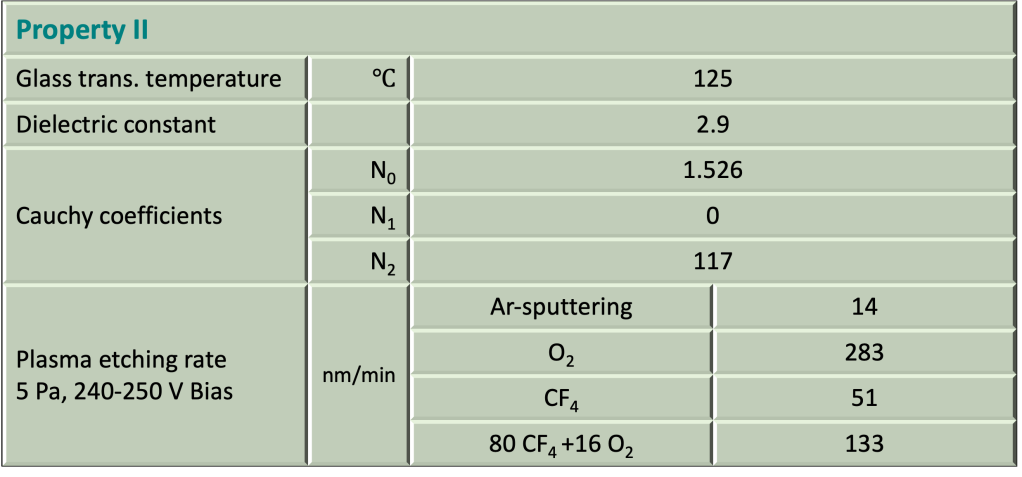

Product properties 產品物性

…

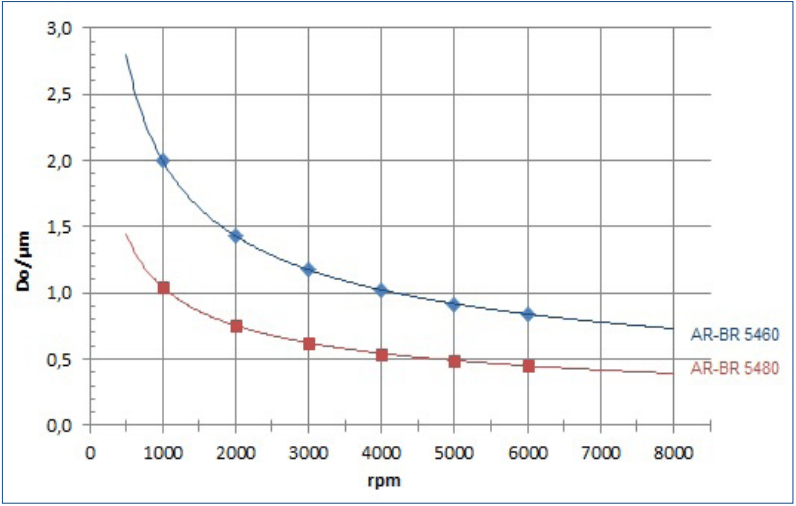

AR-BR 5400 series Spin curve 塗佈曲線

…

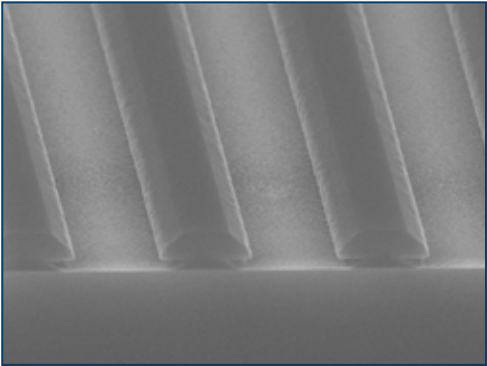

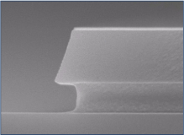

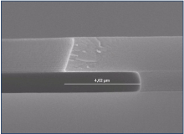

Structure and resolution 結構與解析度

Structure resolution

AR-BR 5460 – AR-P 3510

5 µm-bars of positive two-layer system after development

Resist structure

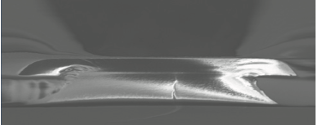

AR-BR 5480 – SX AR-N 4340/7

Finely adjusted lift-off undercut with negative resist

…

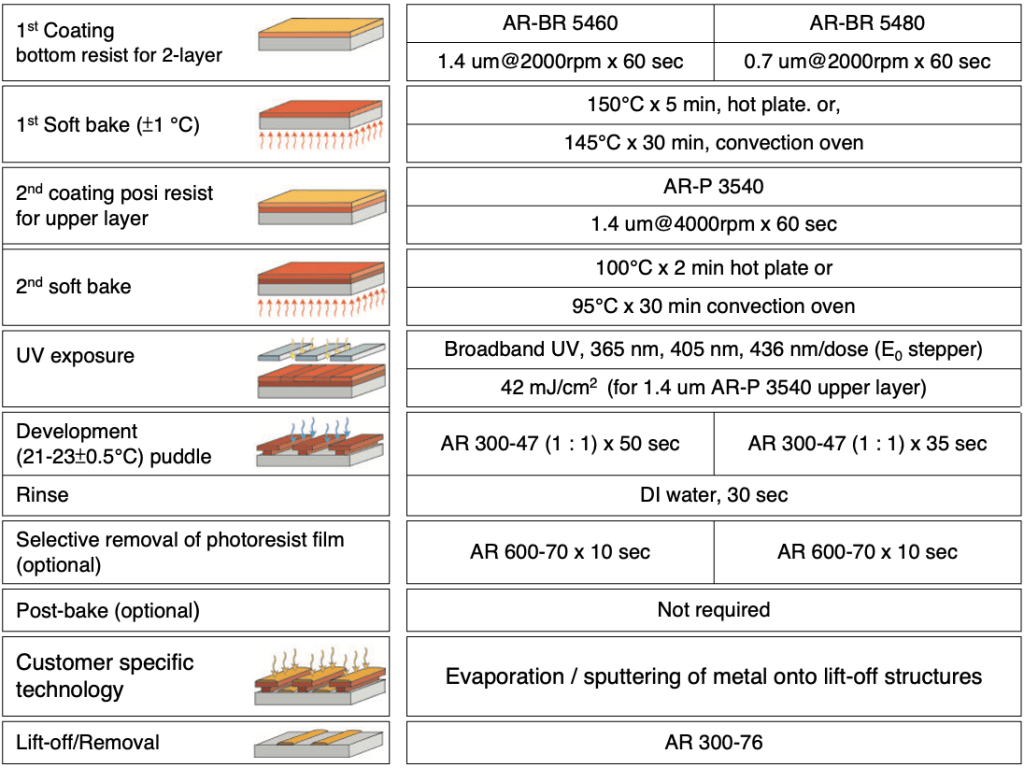

2-layer with positive PR process baseline 與正型光阻製程參數

This diagram shows exemplary process steps for the positive system AR-BR 5400 – AR-P 3540. All specifications are guideline values which must be adapted to own specific conditions. For further information on processing, 👉“ Detailed instructions for optimum processing of photoresists”. For recommendations on wastewater treatment and general safety instructions, 👉”General product information on Allresist photoresists”.

表列為與正型光阻AR-BR 5400 – AR-P 3540 製程參數的範例。所有參數為參考值,使用者應依設備環境實際狀況加以調整。

Processing instructions for positive two-component system

Coating:

The substrate is at first coated with the copolymer AR-BR 5400 and tempered. After cooling to

room temperature, the photoresist is applied onto the copolymer. Dwell times are to be avoided; the liquid photoresist should not be left for more than 10 s on the standing wafer. The film thickness may be varied in a range between 1.6 – 4.0 µm. Subsequently, the two component system is tempered.

Note: The ratio of film thicknesses of both films will affect structural geometry. For a strong lift-off effect, a thin photoresist layer and a thick copolymer layer is advantageous. For a dimensionally accurate transfer of structures into the copolymer layer however, both layers should have approximately the same thickness. The entire system always has to be optimized for the particular application.

塗佈製程:

基板(晶圓)上首先塗佈AR-BR 5400共聚物當底層並軟烤.待基板冷卻至室溫時塗佈正型光阻於底層之上.光阻滴定於基板後需避免延滯超過10秒. 否則膜厚變異可能介於1.6 – 4.0 um之間. 光阻塗佈後再對2層膜厚軟烤.

附註:

兩層材料膜厚比例會影響結構. 薄光阻搭配較厚的底層共聚物可獲得較好的浮剝離(lift-off)效果. 兩層材料厚度一致則底層可獲得較佳的尺寸精確度. 使用者需依實際應用調整厚度比例.

Exposure:

AR-P 3500: Exposure and aqueous-alkaline development are carried out as usual ( 👉Product information AR-P 3500). AR-BR 5400: The copolymer itself is not sensitive in the UV-range between 300-450 nm. The properties of the layer are however adjusted such that the polymer will dissolve quickly in the recommended aqueous-alkaline developer

曝光:

AR-P 3500正光阻曝光及鹼性水溶液顯影依產品基本參數. ( 👉請參考AR-P 3500series 產品資料)

AR-BR 5400底層共聚物對紫外線波長300-450nm不感光. 但可在光阻鹼性水溶液顯影液中快速溶解.

Development:

After the upper photoresist layer is entirely developed in exposed areas, the developer begins to dissolve the copolymer. The dissolution process now takes place in undirected manner (isotropic). AR-BR 5400 is in this process removed both towards the bottom and towards the left or right side so that the undercut is formed. The longer the developer can exerts its effect, the more of the copolymer under the photoresist film is removed by dissolution. For a reduction of the dissolving rate, a higher temperature of up to 180 °C has to be chosen (instead of 150 °C). The desired undercut can thus be adjusted via the parameters temperature and development time (👉 see images below).

25s development 0.8µm undercut

40s development 1.6µm undercut

90s development 4.6µm undercut

Selective removal of the photoresist layer (optional):

For transparent and temperature-stable films, the copolymer layer is used alone. In this case, the residual photoresist is selectively removed after development with remover AR 600-70. The substrate is briefly immersed in remover AR 600-70 and dried immediately with compressed air.

光阻層選擇性去除:

底層材料為耐溫透明結構,可依需求應用,因此光阻顯影後可單獨以AR 600-70去除. 以浸泡式將基本板置於AR 600-70去除液中並立即以壓縮空氣乾燥.

Lifting / Removal:

Removers AR 300-73 and AR 300-76 are both suitable for lifting. If lift-off structures are not thermally stressed during evaporation or sputtering, lifting will take place within a minute. After high thermal load (> 150 °C), the time required for lifting increased considerably. Ultra sound and heating facilitate a removal. Remover AR 300-73 may in this case be heated up to 50 °C max.

懸浮剝離 / 去除:

AR 300-73及AR 300-76兩款去除劑都適合用於懸浮剝離的製程. 如果要被剝離的結構未受蒸鍍或濺鍍高溫影響,應該可在一分鐘之內剝離。

製程溫度如果高於150℃, 剝離所需時間會明顯增加. 可用超音波或加熱去除液改善. AR 300-73去除製程為例,最高可加熱至50℃

…

2-layer with negative PR process baseline 製程參數

This diagram shows exemplary process steps for the negative system AR-BR 5400 – AR-P 4340/7. All specifications are guideline values which must be adapted to own specific conditions. For further information on processing, 👉“ Detailed instructions for optimum processing of photoresists”. For recommendations on wastewater treatment and general safety instructions, 👉”General product information on Allresist photoresists”.

表列為與負型光阻AR-BR 5400 – AR-P 4340/7 製程參數的範例。所有參數為參考值,使用者應依設備環境實際狀況加以調整。

Processing instructions for negative two-component system

The negative two-layer lift-off system is characterized by a particularly high temperature resistance up to 250°C after development.

底層材料搭配負型光阻的雙層浮剝離製程,顯影後結構耐溫可達250℃

Coating:

The substrate is at first coated with the copolymer AR-BR 5400 and tempered. After cooling to room temperature, the negative resist SX AR-N 4340/7 which was specifically designed for two-layer systems is applied onto the copolymer. Dwell times are to be avoided; the liquid photoresist should not be left for more than 10 s on the standing wafer. The film thickness may be varied in a range between 1.0 – 2.5 µm. Subsequently, the two-component system is tempered.

Note: The ratio of film thicknesses of both films will affect the structural geometry. For a strong lift-off effect, a thin photoresist layer and a thick copolymer layer is advantageous. For a dimensionally accurate transfer of structures into the copolymer layer however, both layers should have approximately the same thickness. The entire system always has to be optimized for the particular application.

塗佈製程:

基板(晶圓)上首先塗佈AR-BR 5400共聚物當底層並軟烤.待基板冷卻至室溫時塗佈負型光阻(SX AR-N 4340/7)於底層之上,光阻勢特別設劑用於塗佈於高分子底層之上.光阻滴定於基板後需避免延滯超過10秒. 否則膜厚變異可能介於1.0 – 2.5 um之間. 光阻塗佈後再對2層膜厚軟烤.

附註:

兩層材料膜厚比例會影響結構. 薄光阻搭配較厚的底層共聚物可獲得較好的浮剝離(lift-off)效果. 兩層材料厚度一致則底層可獲得較佳的尺寸精確度. 使用者需依實際應用調整厚度比例.

Exposure:

SX AR-N 4340/7: Exposure and aqueous-alkaline development are carried out according to the general

process descriptions which require an additional crosslinking bake in the negative mode.

AR-BR 5400: The copolymer itself is not sensitive in the UV-range between 300-450 nm. The properties of the layer are however adjusted such that the polymer will dissolve quickly in the recommended aqueous-alkaline developer.

曝光:

SX AR-N 4340/7負型光阻曝光及鹼性水溶液顯影依產品基本參數. 負型光阻需要於曝光後烘烤以進行高分子架橋。AR-BR 5400底層共聚物對紫外線波長300-450nm不感光. 但可在光阻鹼性水溶液顯影液中快速溶解.

Development:

After the upper photoresist layer is entirely developed in exposed areas, the developer begins to dissolve the copolymer. The dissolution process now takes place in undirected manner (isotropic).

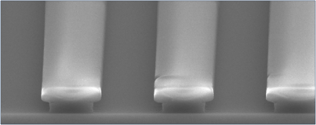

AR-BR 5400 is in this process removed both towards the bottom and towards the left or right side so that the undercut is formed. The longer the developer can exerts its effect, the more of the copolymer under the photoresist film is removed by dissolution. For a reduction of the dissolving rate, a higher temperature of up to 180 °C has to be chosen (instead of 150 °C). The desired undercut can thus be adjusted via the parameters temperature and development time (👉 see images below). In addition, the steepness can be influenced by the exposure time of the negative resist.

顯影:

上層正光阻曝光區完全顯影後,顯影液開始溶解底層的共聚高分子. 但此時的溶解是等向性的. 即AR-BR 5400溶解的方向有向下及左右,因此型成下切結構. 顯影時間越長,底層溶解越多,下切效果越明顯. 底層材料軟烤溫度從150℃提高至180℃可降低溶解率. 因此下切結構可依軟烤溫度及顯影時間調整. (👉請參考下圖). 此外,負型光阻結構的垂直度會受曝光時間影響.

Steep edges due to optimised exposure times of the negative system

Negative lift-off structures after tempering at 200 °C

Selective removal of the photoresist layer (optional):

For transparent and temperature-stable films, the copolymer layer is used alone. In this case, the residual photoresist is selectively removed after development with remover AR 600-70. The substrate is briefly immersed in remover AR 600-70 and dried immediately with compressed air.

光阻層選擇性去除:

底層材料為耐溫透明結構,可依需求應用,因此光阻顯影後可單獨以AR 600-70去除. 以浸泡式將基本板置於AR 600-70去除液中並立即以壓縮空氣乾燥.

Lifting / Removal:

Removers AR 300-73 and AR 300-76 are both suitable for lifting. If lift-off structures are not thermally stressed during evaporation or sputtering, lifting will take place within a minute. After high thermal load (> 250 °C), the time required for lifting increased considerably. Ultra sound and heating facilitate a removal. Remover AR 300-73 may in this case be heated up to 50 °C max.

懸浮剝離 / 去除:

AR 300-73及AR 300-76兩款去除劑都適合用於懸浮剝離的製程. 如果要被剝離的結構未受蒸鍍或濺鍍高溫影響,應該可在一分鐘之內剝離。

製程溫度如果高於250℃, 剝離所需時間會明顯增加. 可用超音波或加熱去除液改善. AR 300-73去除製程為例,最高可加熱至50℃

…