Top surface imaging (TSI) photoresist – principles

Roland and Coopmans (Proc. SPIE 631, 34 (1986)) intensively studied the fundamentals of the top surface imaging technology which is based on a selective resist silylation process (DESIRE process). A positive photoresist specifically optimised for this purpose with considerably increased content of light-sensitive components (LSCs) is exposed image-wise. In exposed areas, indene carboxylic acid is formed from naphthoquinone diazide (LSC; see Wiki Photosensitive components). At the same time, the inhibitory effect of the LSCs protecting the OH-groups of the novolac is reversed (see Wiki Photosensitive components. If now a gas-phase silylation of the surface is performed, organosilicon components (for example HMDS) penetrate the resist layer in irradiated areas and react with exposed OH groups of the novolac. In unexposed areas however, the protection due to the inhibitory effect is still maintained and HMDS is not able to diffuse into the layer. If then an oxygen plasma etching step is carried out, non-volatile silicon oxides (SiOx) are formed in exposed structures (silicon-containing), while volatile oxidation products are formed in non-silylated regions. The resist is consequently removed in these places (dry development of the resist). Since the exposed areas remain, the resist works as negative-tone resist.

It is already sufficient for this process if the organosilicon compound penetrates only 100-200 nm deep into the exposed areas. The resulting SiOx mask of this depth is enough to completely develop also significantly thicker photoresist layers. A high resolution can be achieved due to this thin structure imaging on the surface (top surface imaging). Likewise, a coating and at the same time planarization of topologically structured substrates is very well possible since the imaging process takes only place on the surface. A development with oxygen plasma can easily remove the different layer thicknesses (topologies). This system is furthermore suitable for highly reflective substrates (e.g. aluminium) since no complete exposure down to the bottom is required.

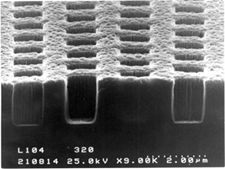

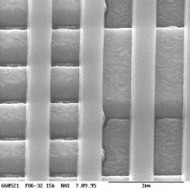

Plasma-developed structures on topologies

SiOx mask of SX AR-N 7100/2

Resist lines after O2-RIE development over aluminum structures with SX AR-N 7100

Allresist now developed a TSI photoresist. Negative resist SX AR-N 7100/2 is a safer solvent-based experimental sample suitable for g- and i-line lithography. After image-wise exposure and gas phase silylation, the resist mask is developed plasma-chemically (O2-plasma). The handling process comprises the following steps:

- Spin coating

- Tempering (100 °C bis 130 °C)

- Exposure (436 nm, 365 nm)

- Pre-tempering silylation (175 °C for HMDS respectively 110 – 130 °C for TMDS)

- Gas phase silylation (165 °C for HMDS respectively 110 – 130 °C for tetramethyldisilazane)

- Dry development (O2 plasma)

The duration of the silylation step depends on the specific technical conditions.

The gas phase silylation can be replaced by liquid silylation.

Overview of photoresist-others

Adaptable two-layer resist AR-BR 5460 for variable lift-off structures

Alkali-stable, easily structurable positive resist SX AR-P 5900/8

Laser direct exposure with AR-P 3540

New procedure for the spray coating of deep topologies with SX AR-P 1250/20

Photoresist coatings on Teflon substrates

Positive resist for temperature sensitive substrates

Positive two- layer lift-off system

Resist for 488 nm exposure wavelength

Spray resists for different topologies (positive and negative)

Thermally stable two-layer lift-off systems

Top surface imaging (TSI) photoresist – principles