PPA for two layer applications

Report on the two layer system, respectively lift-off:

AR P-617 (250nm) with PPA (30nm), development followed by vapor coating of Al (40nm). (5% H2O in IPA resulted in development rate of 0.5 nm/sec.)

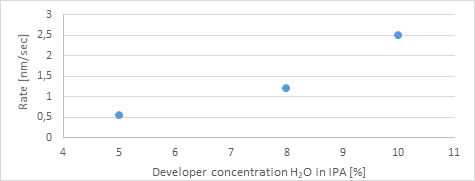

- Development rate of AR-P 617 can be adjusted precisely by means of the water concentration in IPA (5 -10% corresponding to 0,5 – 2,5 nm/s)

Dependence of the development rate of AR-P 617 in developers with variable water concentration in IPA, 21°C, SB 5′ 180°C

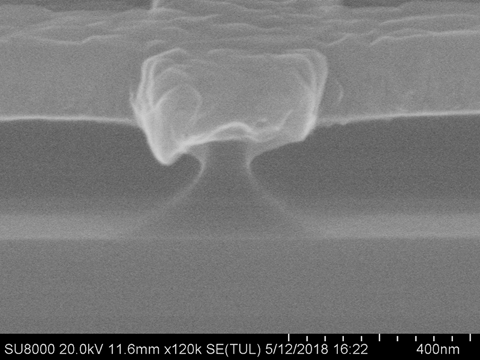

- used very successfully for the production of undercut structures

Bridge with undercut, covered by 40 nm aluminum

Developer:

- 10 w-% of DI-water in IPA

- Stirring!

- Used 130 seconds, which is a 30% overetch

- Evaporation of 40 nm Aluminum. Unfortunately, the layer is quite stressful and it peeled of around the cleaving edge

Results:

- Undercut is nicely visible, bridge is 100 nm wide, which leads to an undercut of 160 nm ([420-100]/2)

- Metal on the silicon was detached during the cleaving.

- At the test structure one can nicely see the residuals in the fields. Most residuals remain for the widest cap, while all caps flew away because they were fully underetched.