New procedure for the spray coating of deep topologies with SX AR-P 1250/20

In the CiS Institute for Microsensors, deep silicon etch grooves are structured for the fabrication of customer-specific components. For this purpose, a coating procedure via spray coating was developed. Extensive experiments were performed with the EVG spray coater, while Allresist optimised the resist used for these investigations. In the end however, the results turned out to be not entirely satisfying since the edges of etch grooves could not be covered sufficiently.

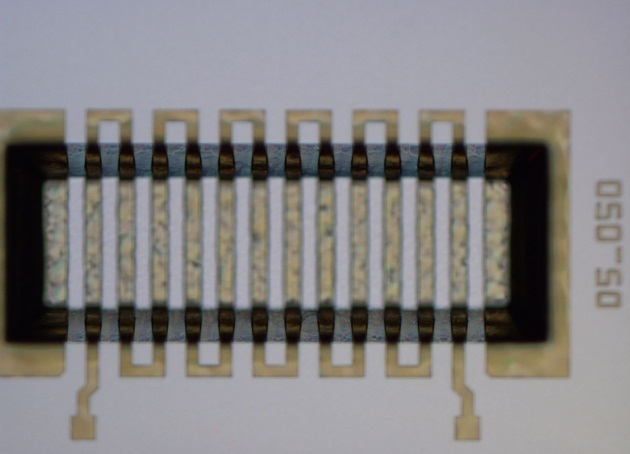

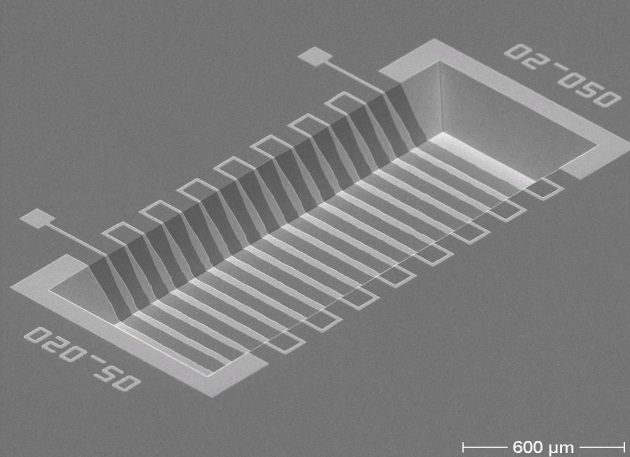

The desired good coverage of edges was only made possible after staff members of the CSI had developed a new spray system. A prerequisite for this development was an even further improved spray resist, SX AR-P 1250/20. In figures 1 and 2, etched structures of silicon grooves are shown. The very good edge coverage of etch grooves is clearly evident in figure 2. The layer is completely closed at the points of interest.

Fig. 1: Resist structures of SX AR-P 1250 for the coverage of etch grooves

Fig. 2: Completely etched test structures after resist removal

Overview of photoresist-others

Adaptable two-layer resist AR-BR 5460 for variable lift-off structures

Alkali-stable, easily structurable positive resist SX AR-P 5900/8

Laser direct exposure with AR-P 3540

New procedure for the spray coating of deep topologies with SX AR-P 1250/20

Photoresist coatings on Teflon substrates

Positive resist for temperature sensitive substrates

Positive two- layer lift-off system

Resist for 488 nm exposure wavelength

Spray resists for different topologies (positive and negative)