UV-structuring of PMMA resists

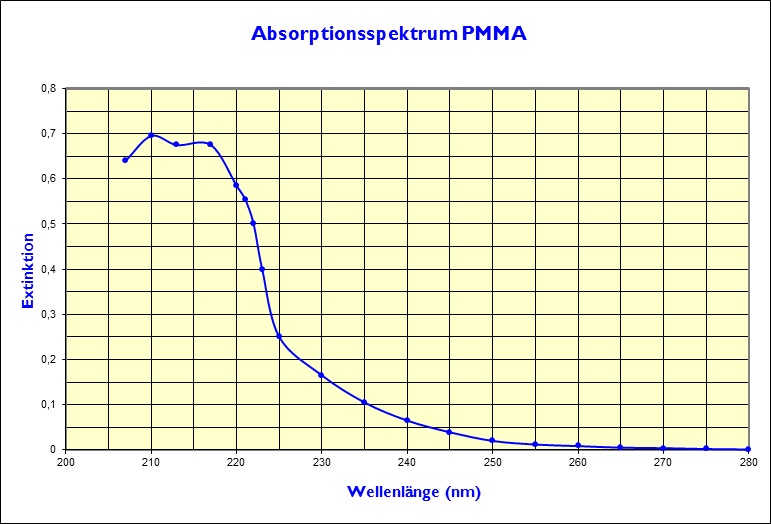

PMMA resists can also be patterned using UV-lithography, but only at exposure wavelengths of 200 – 270 nm (deep UV light). Typically used is the wavelength-range of the lowest line of high-pressure mercury lamps at 254 nm. The image shows the UV absorption spectrum of a PMMA resist. Above a wavelength of 280 nm, the polymer shows no absorption and can thus not be exposed in this wavelength range.

Absorption spectrum of a PMMA.

The sensitivity of PMMA at this wavelength is however low, in particular if high-pressure mercury lamps are used since only a small portion of the radiation is emitted at 254 nm. In addition it has to be ensured that no glass (lenses, filters) are present in the beam paths, since glass is impermeable for light less than 300 nm. Only quartz glass is suitable for 254-nm lithography. If laser light is used as source for the deep UV-lithography, more energy is available for exposure and PMMA resists can consequently be exposed with acceptable exposure times. After exposure, PMMA films are developed according to the procedure used in e-beam lithography (see Development PMMA films).

Overview of photoresist-others

Alkali-stable positive resist obtained after treatment with HMDS

Aqueous negative resist based on gelatine

Atlas 46 for nanoimprint lithography

Ethanol and toluene-resistant photoresist AR-U 4060

Fluorescent resist structures with photoresists

Laser ablation of PPA (Phoenix 81)

Negative CAR PMMA resist SX AR-N 4810/1

Positive polyimide one-layer resist

Resist for near infrared (NIR)

Structuring by ablation of the resist materials

Structuring of polyphthalaldehydes with photolithography

Surface imaging resist system SX AR-N 7100 – silylable photoresist

Top surface imaging (TSI) photoresist – principles

Two-layer photoresist system for water-sensitive substrates

Two-layer resist system for hydrofluoric acid etching

UV-structuring of PMMA resists