Thermostable photoresists

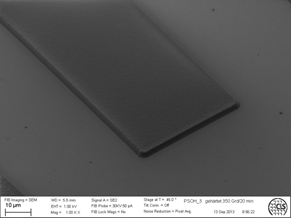

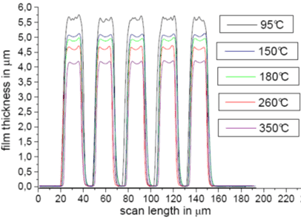

Many applications demand coatings with excellent thermal stability. Structures of the temperature-stable negative resist SX AR-N 4340/6 are able to withstand temperatures of up to 350 °C with high shape accuracy (Fig. 1); merely shrinkage of up to 20% is observed (Fig. 2).

Fig. 1 REM-image of SX AR-N 4340/6 structure tempered at 350 °C with smooth surface and sharp edges

Fig. 2 Temperature-dependent shrinkage, measured with Dektak 150

Structures of the new thermostable positive resists SX AR-P 3500/8 also show a great resistance to very high temperatures as they occur for example in intensive etching or implantation processes. Most commercially available removers easily dissolve resist layers after thermal loads of up to 130 ° C. At higher temperatures however, the aqueous alkaline remover AR 300-73 has to be used. Hardened structures (above 150 ° C) are then inert to solvents, which enables applications in microfluidics.

Overview of photoresist-others

Alkali-stable positive resist obtained after treatment with HMDS

Aqueous negative resist based on gelatine

Atlas 46 for nanoimprint lithography

Ethanol and toluene-resistant photoresist AR-U 4060

Fluorescent resist structures with photoresists

Laser ablation of PPA (Phoenix 81)

Negative CAR PMMA resist SX AR-N 4810/1

Positive polyimide one-layer resist

Resist for near infrared (NIR)

Structuring by ablation of the resist materials

Structuring of polyphthalaldehydes with photolithography

Surface imaging resist system SX AR-N 7100 – silylable photoresist

Thermostable photoresists

Top surface imaging (TSI) photoresist – principles

Two-layer photoresist system for water-sensitive substrates

Two-layer resist system for hydrofluoric acid etching