Structuring by ablation of the resist materials

The basic principle of laser ablation is that laser irradiation of a certain wavelength introduces so much energy into the resist material which is modified for ablation that the resist polymer is destroyed and then vaporizes as low molecular weight fragments. This process can be promoted by introducing suitable dye additives. The result is transparent structures (ablated surfaces) in the otherwise opaque surface.

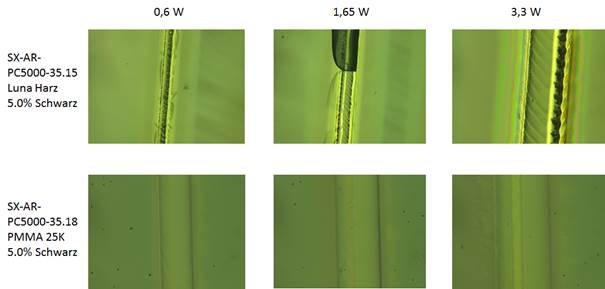

Within the scope of the Photoenco project (June 2016 – May 2019), protective resist samples with dyes were created. Layers of these samples were irradiated with a 532 nm laser of different intensity. The figure demonstrates that with increasing laser power, the layer is completely ablated.

Figure: Lines written with 532-nm laser into PMMA and novolac layers

Resist samples for different laser wavelengths can be manufactured with appropriate dyes.

Overview of photoresist-others

Alkali-stable positive resist obtained after treatment with HMDS

Aqueous negative resist based on gelatine

Atlas 46 for nanoimprint lithography

Ethanol and toluene-resistant photoresist AR-U 4060

Fluorescent resist structures with photoresists

Laser ablation of PPA (Phoenix 81)

Negative CAR PMMA resist SX AR-N 4810/1

Positive polyimide one-layer resist

Resist for near infrared (NIR)

Structuring by ablation of the resist materials

Structuring of polyphthalaldehydes with photolithography

Surface imaging resist system SX AR-N 7100 – silylable photoresist

Top surface imaging (TSI) photoresist – principles

Two-layer photoresist system for water-sensitive substrates

Two-layer resist system for hydrofluoric acid etching