Polyimide two-layer systems

In certain applications it is desirable to keep the original properties of a polymer unchanged, e.g. without addition of light-sensitive components like for example for a use as moisture sensor.

The patterning of the pure polyimide resist (SX AR-P 5000/80) is in this case possible using a two-layer system analogue to AR-P 5400 / AR-P 3500.

For this application, a surprisingly simple procedure was developed:

Table 1: Process parameters for the two-layer polyimide process

The double coating can be carried out without any problems. After exposure, development of the photoresist and the polyimide is performed in one step. Removal of the now superfluous photoresist layer can easily be realized by flood exposure and another development step using a weaker developer.

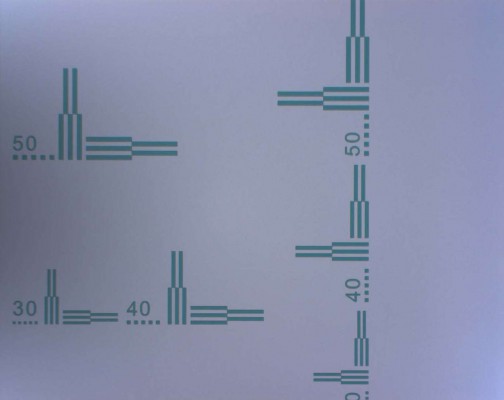

Image 1: Structures of the pure polyimide after removal of the photoresists, film thickness of 600 nm

Overview of photoresist-others

Alkali-stable positive resist obtained after treatment with HMDS

Aqueous negative resist based on gelatine

Atlas 46 for nanoimprint lithography

Ethanol and toluene-resistant photoresist AR-U 4060

Fluorescent resist structures with photoresists

Laser ablation of PPA (Phoenix 81)

Negative CAR PMMA resist SX AR-N 4810/1

Polyimide two-layer systems

Positive polyimide one-layer resist

Resist for near infrared (NIR)

Structuring by ablation of the resist materials

Structuring of polyphthalaldehydes with photolithography

Surface imaging resist system SX AR-N 7100 – silylable photoresist

Top surface imaging (TSI) photoresist – principles

Two-layer photoresist system for water-sensitive substrates

Two-layer resist system for hydrofluoric acid etching