Fabrication of vertical flanks with CAR 44

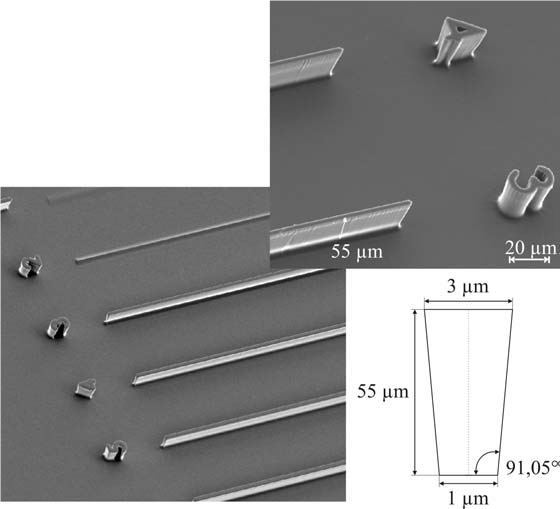

AR-N 4400-50 was investigated at the TU Braunschweig with particular regard to the fabrication of well-defined resist architectures with vertical flanks. CAR44 layers of variable layer thickness were dried on a hotplate at 95 °C; the required optimum softbake time was estimated to about 1 minute per micrometre layer thickness. The minimum exposure dose for adequate crosslinking and vertical edge formation was determined to about 26 mJ/cm2 per micrometre layer thickness. After the PEB step at 95 °C mandatory for crosslinking, the development was carried out at room temperature supported by ultrasonic treatment. The additional agitation provides an accelerated development procedure down to deeper layers which reduces the development times. Using this optimized process control, structures with an aspect ratio of more than 18:1 and flank angles of approximately 91 °C could be achieved.

Figure: Aspect ratio and flank angle of CAR44 determined on the basis of test structures.

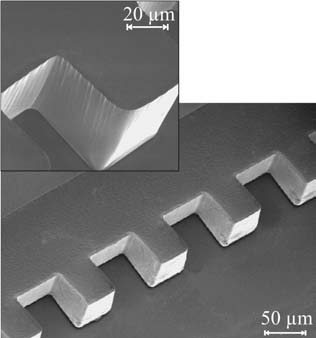

Figure: Electroplated metal structures in stable CAR44 galvanoforms.

Due to high form stability and, in contrast to SU-8, very good removing properties, the resists of the CAR44 series (AR-N 4400) are excellent for galvanic applications.

Overview of negative photoresist

Alkali-stable and solvent-stable negative resist

Chemically enhanced negative resist (Process parameters and resolution)

Chemically enhanced negative resist without cross-linking

Coloured negative photoresists

Development of thick negative resist layer

Dose-dependent structure size with negative resists

Fabrication of vertical flanks with CAR 44

Generation of undercut structures with negative resists

Negative polyimide photoresist

Negative two- layer lift-off system

NIR-laser structurable photoresists

poly(hydroxystyrene) and (hydroxystyrene-co-MMA) photoresist with high-temperature stability

Sensitive negative PMMA resist (CAR)

Sensitive negative resist for 405 nm laser direct exposure