3-layer system CSAR/PMMA-co-MA/PMMA

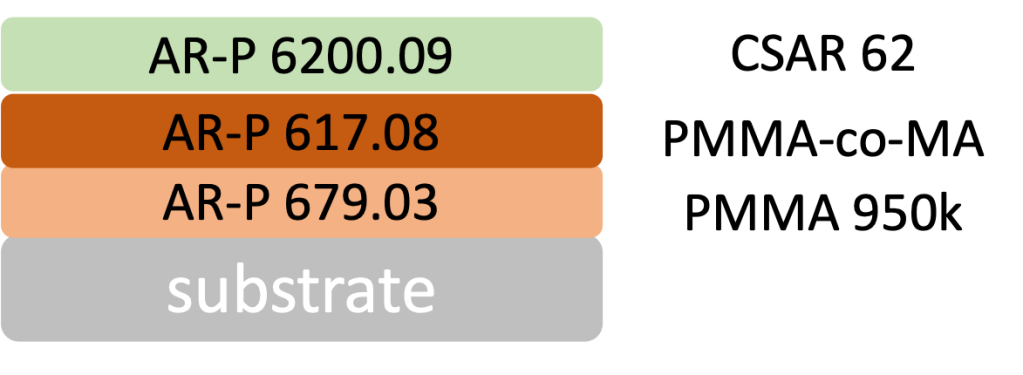

A further variant for the structure of three-layer systems uses 950k PMMA as bottom resist, AR-P 617 as middle layer and CSAR 62 as top resist:

Schematic representation of three-layer system: 950k PMMA (bottom), PMMAcoMA (middle), CSAR 62 (top)

There is no mixing during the coating, thus ensuring a defined layer buildup. AR-P 617 can be coated on all PMMA’s (50k – 950k) without any problems, besides, the coating with AR-P 6200 (CSAR 62) is successful as well since anisole does not dissolve AR-P 617. By use of selective developers after exposure, the T-gate architecture can be regulated well. The high-contrast developer AR 600-546 and also the stronger developer AR 600-549 as well as MIBK, o-xylol and ethylbenzene develop in a very selective manner the upper resist layer. The middle layer can likewise be developed very selectively with X AR 600-50/2 or AR 600-50. Finally, developers containing MIBK (AR 600-55 or AR 600-56) can be used for the bottom layer.

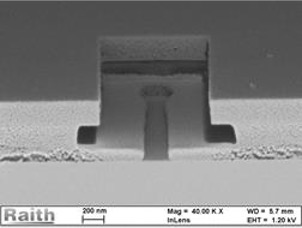

These procedures are presented elaborately in a paper for the MNE 2017, here is a structure made possible by this system.

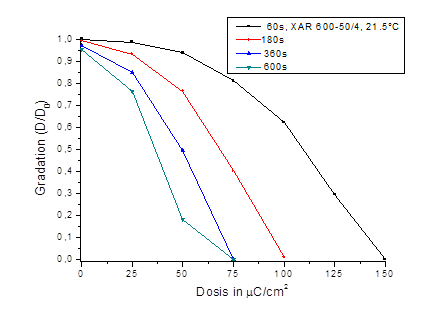

It is a disadvantage for some users, though, that the developer must be changed several times during the process. Therefore, a developer mixture was needed which defines and sufficiently develops all layers. Many strong developers effectuate a distinct dark erosion. By smart combination of an active (developing) component with an admixture that inhibits development, the dark erosion can be reduced. The simultanoeus reduction of sensitivity can be compensated slightly by a prolongation of the development time. The dark erosion of CSAR 62 in X AR 600-50/4 is less than 5%, even after 10 minutes of development.

Dose scale for CSAR 62 (AR-P 6200), SB 180°C, layer thickness: ~240nm, 100 kV, developer X AR 600-50/4, gradation curves dependent on development time at 21.5°C, stopper IPA.

The universal developer X AR 600-50/4 can be used to develop CSAR 62 as well as AR-P 617 (PMMAcoMA) and PMMA in a very sensitive manner. Special developer X AR 600-50/4 is well suited for the development of AR-P 617 as well as CSAR 62 and 950k PMMA, and thus can be used as universal developer for 2- or also 3-layer processes. The sensitivity and thus also the characteristic undercut in the middle layer can well be adjusted by exposure dose and, making use of the dark erosion, by the development time. The developer causes a certain dark erosion of approximately 18nm at 21°C and a development time of 60s. An extension of the development time to 3 minutes also raises the dark erosion significantly to approximately 95nm at 21°C, but only about 80nm at 19°C. Generally, dark erosion can be decreased and contrast slightly raised by reduction of the developer temperature.

Related articles EBL positive

CSAR 62 related

3-layer system CSAR/PMMAcoMA/PMMA

3-layer system for T-gate CSAR/PMMAcoMA/PMMA

BOE etching of SiO2 with CSAR 62 mask

Collapse of extreme high-resolution e-beam resist structures

CSAR 62 Avoidance of particles during large-area exposures

CSAR 62 – Development at low temperatures

CSAR 62 – Experimental studies on new, sensitive developers

CSAR 62 lift-off for thick layers

CSAR 62 nanostructures written at 100 kV

CSAR 62 single layer lift-off system

Evaluation of various developers for e-beam exposed CSAR 62 layers (100 kV)

HF etching of GaAs with CSAR 62 masks

Manufacture of plasmonic nanostructures with CSAR 62

Use of CSAR 62 for the manufacture of nanostructures on GaAs substrates