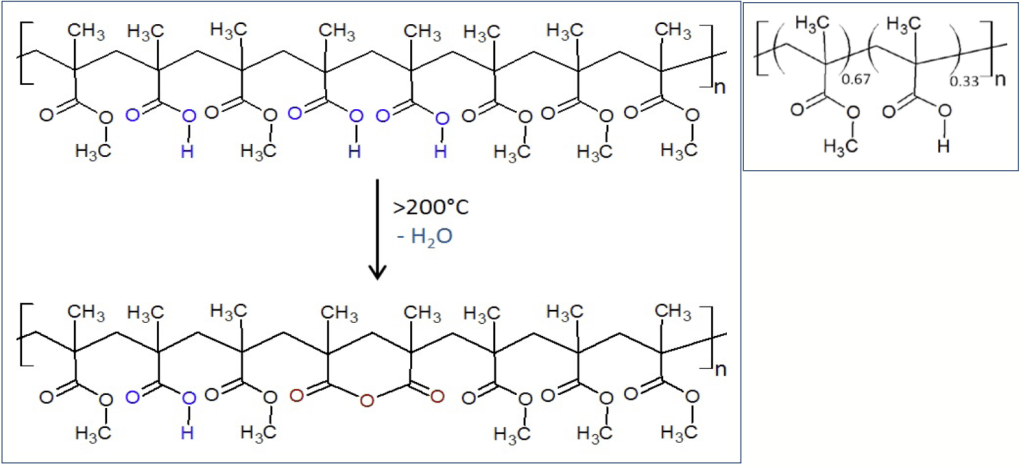

Highly sensitive e-beam resist AR-P 617 (PMMA-copolymer)

The copolymer composed of methyl methacrylate and methacrylic acid is, in contrast to the pure PMMAs, able to form a 6-membered ring during thermal loading. In this case, two methacrylic acid groups must be located adjacent to each other in the polymer chain (see structural formula), which statistically occurs with sufficiently high frequency at a mixing ratio of 2: 1 (PMMA: methacrylic acid). The reaction is possible at a temperature of 190-210 ° since the produced water is a very good leaving group. During irradiation with electrons, the formed 6-membered ring is easier to break apart than the aliphatic radical chain. This results in a higher sensitivity of the copolymer. The adjusted sensitivity then remains unchanged, a reverse reaction with ring opening is impossible.

Fig.: Dehydration of the PMMA copolymer

See New developer for AR-P 617

Related articles EBL positive

CSAR 62 related

3-layer system CSAR/PMMAcoMA/PMMA

3-layer system for T-gate CSAR/PMMAcoMA/PMMA

BOE etching of SiO2 with CSAR 62 mask

Collapse of extreme high-resolution e-beam resist structures

CSAR 62 Avoidance of particles during large-area exposures

CSAR 62 – Development at low temperatures

CSAR 62 – Experimental studies on new, sensitive developers

CSAR 62 lift-off for thick layers

CSAR 62 nanostructures written at 100 kV

CSAR 62 single layer lift-off system

Evaluation of various developers for e-beam exposed CSAR 62 layers (100 kV)

HF etching of GaAs with CSAR 62 masks

Manufacture of plasmonic nanostructures with CSAR 62

Use of CSAR 62 for the manufacture of nanostructures on GaAs substrates