CSAR 62 – Experimental studies on new, sensitive developers

CSAR 62 layers can also be patterned by intensive exposure to UV light. Irradiated films were in this experiment developed with different solvents and the observed sensitivities were compared with each other.

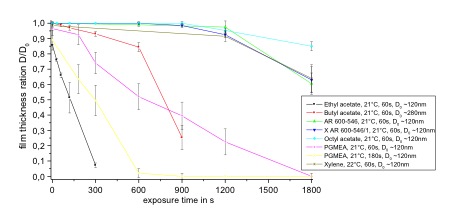

UV-exposed CSAR 62 layers: Comparison of developer strength and erosion rate of different solvent developers

Not surprisingly, the solvents used to obtain the highest possible contrast result in the lowest sensitivity. These weak developers AR 600-546, X AR 600-546/1 and xylene displayed very similar properties. Virtually no dark erosion occurs, and only after a certain threshold dose, the developer shows any effect at all. PGMEA however causes an almost linear development process which is typical of strong developers. Extending the development time from 60 s to 180 s leads here to a significant increase in sensitivity with at the same time low dark erosion of only approx. 12 nm. The highest sensitivity was observed for ethyl acetate (acetic acid). Mixtures with isopropyl cause a considerable decrease of the dark erosion rate, while the sensitivity is at the same time only slightly reduced.

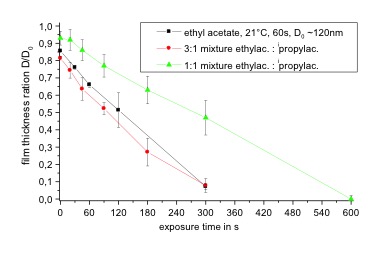

CSAR 62 layers irradiated with UV light: Comparison of developer strength and erosion rates of different mixtures of ethyl acetate with isopropyl acetate

Mixtures containing 25 % isopropyl acetate show approximately the same sensitivity as pure ethyl acetate developers. In 1:1 developer mixtures however, the sensitivity is halved. Better results can possibly be achieved by extending the development time since the development speed is apparently significantly slowed down after addition of 50 % isopropyl acetate to ethyl acetate and thus the course of development can better be controlled.

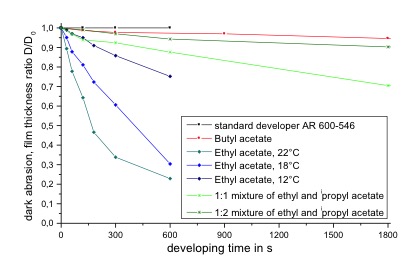

The dark erosion of ethyl acetate can furthermore also be reduced to acceptable levels (~ 5-10 % dark erosion for the generally used development times of < 2 minutes by decreasing the developer temperature to 12℃ or 18℃.

Erosion rates of different acetate developers

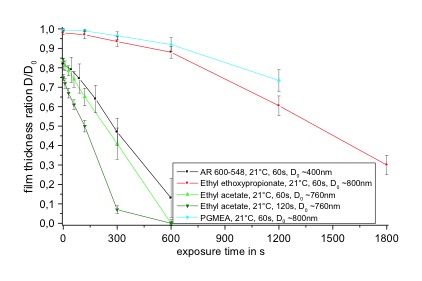

Quite evidently, a certain amount of dark erosion can more likely be tolerated if thicker layers are used as compared to very thin layers. The observed removal rate depends on the kind of resist, the developer used and the temperature, but not on the respective layer thickness. While for example a removal of 100 nm is hardly noticeable at a film thickness of 800 nm, a 100 nm layer is already completely removed in this case.

The strong standard developer AR 600-548 and ethyl acetate are also suitable as developers for thicker CSAR 62 layers and show a very similar course of development at almost identical sensitivities. In the case of ethyl acetate, extending the development time from 60 s to 120 s increases the sensitivity even further.

Thicker UV-exposed CSAR 62 layers: Comparison of developer strength and erosion rates

PGMEA and ethyl ethoxypropionate (EEP) result in lower sensitivities, but on the other hand are unexposed resist areas in contrast to AR 600-548 or ethyl acetate only marginally attacked. Extending the development time and/or a development at higher temperatures would most likely result in an increased sensitivity.

Related articles EBL positive

CSAR 62 related

3-layer system CSAR/PMMAcoMA/PMMA

3-layer system for T-gate CSAR/PMMAcoMA/PMMA

BOE etching of SiO2 with CSAR 62 mask

Collapse of extreme high-resolution e-beam resist structures

CSAR 62 Avoidance of particles during large-area exposures

CSAR 62 – Development at low temperatures

CSAR 62 – Experimental studies on new, sensitive developers

CSAR 62 lift-off for thick layers

CSAR 62 nanostructures written at 100 kV

CSAR 62 single layer lift-off system

Evaluation of various developers for e-beam exposed CSAR 62 layers (100 kV)

HF etching of GaAs with CSAR 62 masks

Manufacture of plasmonic nanostructures with CSAR 62

Use of CSAR 62 for the manufacture of nanostructures on GaAs substrates