BOE etching of SiO2 with CSAR 62 mask

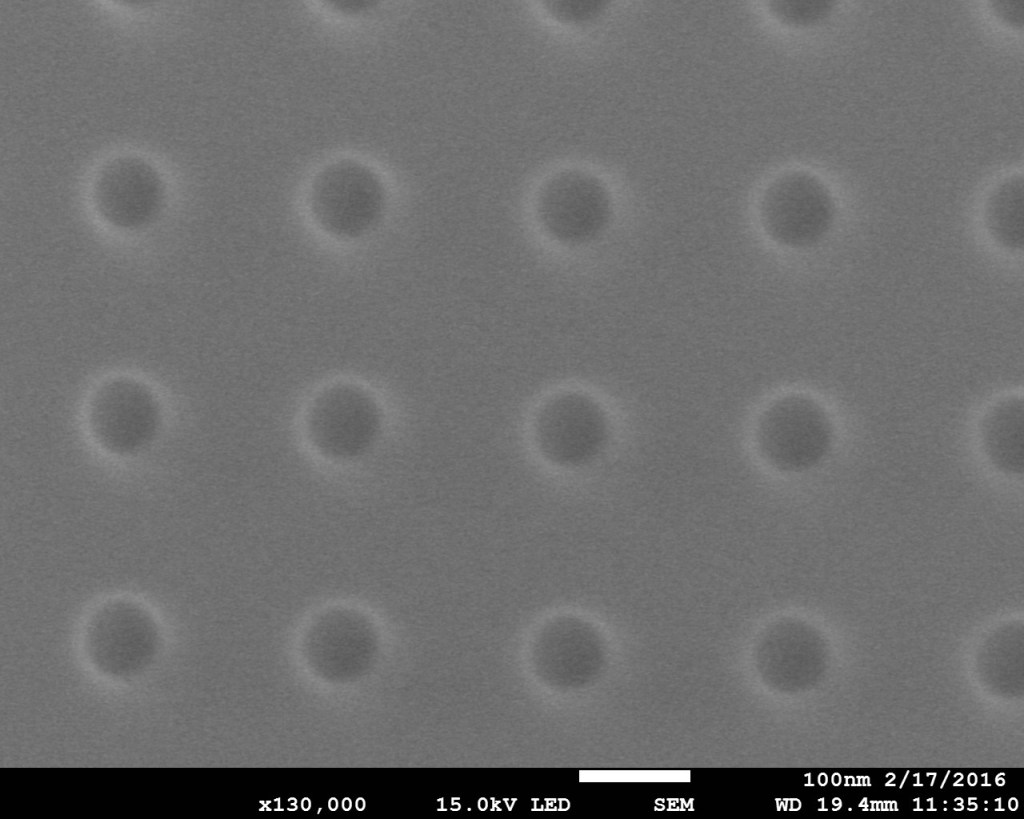

Many applications involve an etching step to transfer the structures produced by means of lithography onto a substrate. Frequently used for this purpose are plasma etching procedures. For certain processes however it is advantageous to etch wet-chemically. These often highly aggressive procedures require a very good resist adhesion and excellent resist stability, especially if hydrofluoric acid solutions are used. Diluted HF solutions with up to about 6 % HF content are well tolerated by almost all resists for a certain amount of time. The stability of the resist is increased even further if buffered HF solutions (BOE process, mixture of HF and NH4F) are used. Even the highly sensitive e-beam resist CSAR 62 can be used as mask for an etching process with HF (BOE, 10:1). Mr. Y. Nori (Lancaster University, Department of Physics, UK) successfully transferred perforation structures with a diameter of 50 nm from the CSAR 62 mask into a SiO2 layer (25 nm SiO2 on Si) with this etch solution. The etching time was 1 minute, the resist film was stable and showed no signs of removal.

Fig.: Perforation structures written in CSAR 62; structures transferred via BOE etching into SiO2

Related articles EBL positive

CSAR 62 related

3-layer system CSAR/PMMAcoMA/PMMA

3-layer system for T-gate CSAR/PMMAcoMA/PMMA

BOE etching of SiO2 with CSAR 62 mask

Collapse of extreme high-resolution e-beam resist structures

CSAR 62 Avoidance of particles during large-area exposures

CSAR 62 – Development at low temperatures

CSAR 62 – Experimental studies on new, sensitive developers

CSAR 62 lift-off for thick layers

CSAR 62 nanostructures written at 100 kV

CSAR 62 single layer lift-off system

Evaluation of various developers for e-beam exposed CSAR 62 layers (100 kV)

HF etching of GaAs with CSAR 62 masks

Manufacture of plasmonic nanostructures with CSAR 62

Use of CSAR 62 for the manufacture of nanostructures on GaAs substrates