AR-P 617 Two layer lift-off system

An alternative version of the structure of two layer systems emanates from only one resist: AR-P 617 (PMMAcoMA 33)

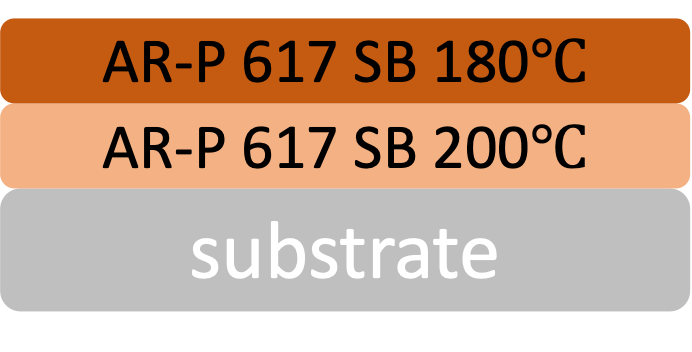

Schematic representation of the two layer system:

AR-P 617, SB 200°C (bottom),

AR-P 617, SB 180°C (top)

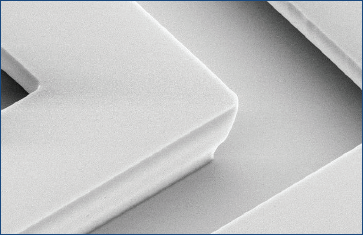

At increasing temperature, AR-P 617.08 becomes linearly more sensitive (coat thickness 680 nm):

The bottom layer is tempered at 200°C for 10 – 20 minutes, afterwards coated with AR-P 617 and again tempered with the upper layer, however, at only 170 – 180 °C. There is no mixing during the coating, which ensures a well-defined layer composition. The resist sensitivity grows with increasing soft bake temperature, therefore AR-P 617 is about 20 % more sensitive at a post-cure of 200 °C compared to 180 °C. Thus, the dose can be systematically adjusted. After development with AR 600-50 or also MIBK/IPA, well-defined lift-off structures result:

Undercut resist architecture after development with AR 600-50:

bottom layer 400nm thick,

top layer 500nm thick

Related articles EBL positive

CSAR 62 related

3-layer system CSAR/PMMAcoMA/PMMA

3-layer system for T-gate CSAR/PMMAcoMA/PMMA

BOE etching of SiO2 with CSAR 62 mask

Collapse of extreme high-resolution e-beam resist structures

CSAR 62 Avoidance of particles during large-area exposures

CSAR 62 – Development at low temperatures

CSAR 62 – Experimental studies on new, sensitive developers

CSAR 62 lift-off for thick layers

CSAR 62 nanostructures written at 100 kV

CSAR 62 single layer lift-off system

Evaluation of various developers for e-beam exposed CSAR 62 layers (100 kV)

HF etching of GaAs with CSAR 62 masks

Manufacture of plasmonic nanostructures with CSAR 62

Use of CSAR 62 for the manufacture of nanostructures on GaAs substrates